Mobile Crane Search Result

Floating crane

Floating Cranes are used mainly in bridge building and port construction, but they are also used for occasional loading and unloading of especially heavy or awkward loads on and off ships. Some floating cranes are mounted on a pontoon, others are specialized

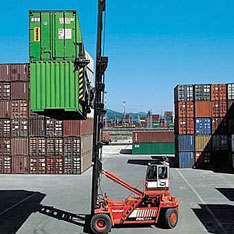

Side lift crane

A side lifter Crane is a road-going truck or semi-trailer, able to hoist and transport ISO standard containers. Container lift is done with parallel crane-like hoists, which can lift a container from the ground or from a railway vehicle.

Stacker crane

The crane moves on a track in an aisle of the warehouse. The fork can be raised or lowered to any of the levels of a storage rack and can be extended into the rack to store and retrieve product. The product can in some cases be as large as an autoMobile. Stacker cranes are often used in the large freezer warehouses of frozen food manufacturers. This automation avoids requiring forklift drivers to work in below freezing temperatures every day.

Truck

A truck, also named lorry, is a motor vehicle designed to transport cargo. Trucks vary greatly in size, power and configuration, with the smallest being mechanically similar to an autoMobile. Commercial trucks can be very large and powerful, and may be configured to mount specialized equipment, such as in the case of fire trucks and concrete mixers and suction excavators. Modern trucks are powered by either gasoline or diesel engines,

All Terrain Crane

As the name suggests, all-terrain cranes can manoeuvre through rough terrain as well as public roads with ease. These cranes are technologically the most advanced of all the Mobile Cranes. They come in both lattice-type and telescopic-type boom options. All terrain cranes that are ideal for both on and off-road construction and industrial projects. Regardless of the location, temperature or climate, all-terrain cranes are

Telescopic crane

or decrease the total length of the boom. These types of booms are often used for short term construction projects, rescue jobs, lifting boats in and out of the water, etc. The relative compactness of telescopic booms make them adaptable for many Mobile applications.

Tower crane

Tower Crane is a modern form of balance crane that consist of the same basic parts. Fixed to the ground on a concrete slab, tower cranes often give the best combination of height and lifting capacity and are used in the construction of tall buildings. The

Mobile Cranes

fixed in the ground or mounted on certain vehicles. Cranes are operated either through cab operator or through infrared or radio signals. The important equipments of the cranes are mast, base, jib and motor. Stationary cranes are fixed whereas Mobile Cranes are those cranes which are mounted on trucks, trailers, or other engineering vehicles. Mobile cranes can be classified into four major categories: (1) truck crane; (2) crawler crane, (3) rough-terrain crane; and (4) all-terrain crane. These

FAQ About Mobile Crane

- Types of Cranes

- New requirements about crane maintenance and competent inspecting person

- Construction and Maintenance of Cranes and Lifting Appliances

- Stability of Cranes and Lifting Appliances

- YGMT Crane types

- Cranes, lifting appliances and fork lift trucks

- Crane Lifting Operations - Operators of Cranes and Certain Lifting Appliances

- Crane History

- Raw Materials of manufacture cranes

- Cranes,overhead traveling crane,Construction cranes,Tower cranes,Mobile cranes,Articulating cranes

- The Manufacturing Process Of Crane

- Overhead Crane and Bridge Crane

- FACTORS BEHIND THE SELECTION OF CONSTRUCTION EQUIPMENTS

- PORTABLE TRUCK-MOUNTED CRANE BOOMS

- Hydraulic Telescoping Gantries

- Mobile Cranes

- All-Terrain Carriers

- Mobile Crane Tower Attachments

- Tower-mounted crane

- Crane and Mobile Crane

- Mobile Crane Clearances

- Mobile Crane Clearance In Tight Quarters

- Mobile Crane Ground Support Capacity

- MOBILE CRANES INTRODUCTION

- Material Handling Solutions

- What Are Telescopic Cranes?

- Crane Gantry

- What should be taken into account when choosing asphalt plant (ABZ)

- Self Propelled Cranes

- Lorry Mounted Cranes

- General requirements of the safe operation of crane drivers

- Oregon OSHA’s new crane standard for the construction industry

- BossBuyer Gantry Cranes

of Cranes There are many types of cranes. Four of these are tower cranes, rough terrain cranes, truck cranes, and crawler cranes. Rough terrain cranes have large wheels that allow them to move throughout a job site. Truck cranes are Mobile Cranes. This means their bases can move. A truck is the base for the truck crane. Crawler cranes have tracks instead of tires. The tracks keep the crane from sinking into the soil. The tracks make the crane move much slower. So, large trucks

What changes have been made affecting crane maintenance and inspection? Owners of Mobile and tower cranes must now declare on plant registration application and renewal forms that their cranes have been effectively maintained and inspected by a competent person. What are the new requirements for cranes? For new applications

and followed. This is particularly relevant in the case of tower cranes where erection and dismantling must be carried out strictly in accordance with the manufacturers instructions. The erection of jibs on cranes, especially Mobile Cranes, must follow the sequence described in the manufacturers instructions and each section must be identifiable with the crane in which it is normally used. The jib section must have been tested when assembled on the crane and only

examine the anchorage and ballast arrangements as soon as practicable after a crane has been subjected to such weather conditions. A crane is not to be used again until all necessary steps have been taken to ensure its stability. All Mobile Cranes must be fitted with level indicators. The indicators must be fixed in a position where they can be easily seen by the crane driver.

Nuclear power station polar crane, bridge girder erection machine and other special cranes. YGMT has provided 6000 cranes in the industry field of metallurgy, hydropower station, nuclear power station, heavy mining, machinery, energy, railway, autoMobile, etc. YGMT will continue to persist in scientific views of development, and to promote the product brand and enterprise image. With the sense of superior products and honesty, it will continuously meet customer’s demands of high quality

the machine. The machine must be able to impart controlled three dimensional movement to the load whilst the load is secured to the suspended hook or other device. The following machines are cranes within the meaning described above Mobile jib cranes Overhead travelling cranes Lorry mounted cranes Derrick cranes Tower cranes Container cranes Portal jib cranes A machine used to raise persons to elevated positions for the purposes of working on road lighting

a machine for training purposes provided he is under the direct and constant supervision of a person who has been so certificated. It does not follow that a competent operator of say a tower crane, will automatically be competent to drive a Mobile jib crane. The competency of a driver will depend on his ability to handle the particular machine which he is operating. The following are some of the factors which should be considered before an operator is certificated Be at least

they became widely available. In the United States, cranes were often used in locations far away from residential areas. Cranes tended to be built with the boom connected to a trolley, which could be moved easily from place to place. These Mobile Cranes tended to be powered by internal combustion engines. During the 1950s, the availability of stronger steels, combined with an increased demand for taller buildings, led to the development of cranes with very long booms attached to small

to atmospheric corrosion and are better suited to welding than carbon steels. Depending on the exact design of the crane, a wide variety of other materials may be used in manufacturing. Natural or synthetic rubber is used to make tires for Mobile Cranes. Certain structural components may be manufactured from various metals such as bronze and aluminum. Electrical components may include copper for wires and semiconducting elements such as silicon or germanium for electronic circuits.

an overhead traveling crane has the advantage of causing no obstruction in the work area. Cranes used in construction often perform a variety of tasks and must be controlled by highly skilled operators. Construction cranes are divided into Mobile Cranes and tower cranes. Mobile cranes are mounted on trucks or crawlers in order to travel from place to place. An articulating crane is a mobile crane in which there is a joint between two sections of the boom, allowing it to move in a

from the necessary components. As the crane moves along the assembly line, the steel components are welded or bolted into place. The exact procedures followed during this process vary depending on the type of crane being assembled. For a Mobile Crane, the components are then assembled to a standardized truck or crawler of the appropriate type.The assembled crane is tested and shipped. Depending on the size and type of crane, it may be broken down into subsections to be assembled on

paper equipment so as tofacilitate installation of these extremely heavy objects. When making a facility making use of lots of heavy machines, the costs of a bridge crane could be mostly offset in somecircumstances with savings from not leasing Mobile Cranes. The overhead Rotary crane has one of the bridge ends are attached on a fixed pivot with the other end being carried on anannular track. The bridge can transverse across the circular area below. Rotary Overhead cranes provide improvement

the soil and profile of a site may dictate whether to go for a crawler-mounted equip- ment or a wheel-mounted equipment. If there is a power line at or in the vicinity of site, one may go for a fixed-base kind of equipment rather than a Mobile kind of equipment. Similarly, climatic conditions such as the presence of strong winds, visibility level and noise level may affect equipment-selection decision. Further, the access leading to the site may also affect the decision. Heavy

would be unloaded for the construction. A truck crane is designed for a more permanently attached boom and does not have much flat platform area to carry materials. That type of lifting and hoisting equipment is considered and discussed as a Mobile Crane in the next section.

Telescophig gantries are typically used for heavy lifting where Mobile Cranes or derricks are not feasible, where classic "jack and slide" procedures are awkward, or where other conditions make use of the gantry the most economical means to perform the work required. These systems first came into regular use for

There was a time when Mobile Cranes were identified with the United States and taker cranes with Europe, but the globalized modern market for all cranes now transcends regions and borders, blurring these differences. The original author of this book liked to recall a yam

First appearing in Europe during the late 1970s, the all-terrain crane now accounts for a majority of Mobile-crane sales throughout the world. The carriers used on these telescoping cantilevered-boom machines combine the high road speeds of truck carriers with some of the off-road capabilities of the rough-terrain crane. Large-capacity multiaxle

Some older Mobile Crane models can be equipped with an optional front-end attachment composed of a fixed vertical tower pinned at the position on the superstructure where a boom is ordinarily mounted. A luffing boom is affixed at the tower top, and ajib

Much like a Mobile Crane, a tower-mounted crane moves loads by executing three motions: the hook is raised and lowered by means of a winch and fall, carried in a circular path by the swing gear, and carried in a radial motion by either luffing the jib or rolling

happens. And when it does happen the cost will be intolerable. More cerebral demands on the operator reflect changes both in construction equipment and construction culture. Risk managementnot bravado-is the new order of the day in Mobile Crane practice. An underlying rule of this practice is that a balance must be struck between safety and economy. Success demands well-structured organization and unrelenting attentiveness to details. A successful mobile crane operation

long that it will swing into nearby structures. The tail end of the superstructure requires a clear swing path, too. And, after completing the work, the crane must be able to extricate itself and lower its boom for dismantling. Far from all Mobile-crane lifts run against these constraints, but they are common enough to demand attention. It is embarrassing, to say the least, to send a crane to a job only to find that it is incapable of placing the loads where needed. Embarrassment

It is remarkable how a Mobile Crane, by its very nature a huge appa ratus, is routinely shoehorned into snug urban or industrial settings. The means of getting the crane assembled and into a postage-stamp sized position is a subject unto itself. Once there and operating,

planning; evaluation of the actual soil by an experienced person, preferably a licensed professional engineer, is certainly advisable if any doubt exists about soil capacity. Ground surfaces can conceal places of potential peril for Mobile Cranes traveling or working. Pavements may cover vaults, poorly consolidated backfill, or voids where fine-grained soils have washed out. The variety of soil conditions encountered in crane work is as wide as the field of soil mechanics.

Mobile CraneS (a) Truck mounted (b) Crawler mounted (c) Rail mounted locomotive (d) Floating cranes (e) Sky cranes Mobile crane (power driven) includes all type of traveling jib cranes, such as truck mounted, crawler mounted, and locomotive

We are dedicated to increasing quality and customer service standards to exceed our customers' positive expectations. YJM takes pride in on-time, error-free shipments as well as the industry's best product warranty- 5 years on most products. Mobile Material Handling YJM's Fixed and Adjustable Height Steel Gantry Cranes provide an economical way to lift materials anywhere in a facility. The wheels enable you to move the gantry around your facility. This is a more cost-effective lifting solution

Cranes like the telescopic cranes are often used in day-to-day hauling operations but it has also to be noted that these heavy cranes are very important when it comes to carrying out maneuvering operations in ports as well. Telescopic cranes are Mobile in the sense that they transport goods and items in a flexible manner. Also since telescopic cranes are further equipped with height adjustments, when it comes to hauling and transferring the goods from one place to another, the problems related

stone relief in Haterii’s tomb of 1st century Rome, which depicts a monument being built with a sort of crane, that cranes were used in medieval shipyards and ports in Poland. The various types of cranes in common use are railroad cranes, Mobile Cranes, telescopic cranes, tower cranes, truck-mounted cranes, rough terrain cranes, crawler cranes, loader cranes, floating cranes, gantry cranes and aerial cranes. A crane mounted on a railroad car or on a flatcar is known as railroad crane.

vary considerably. The most powerful ABZ is more profitable three times than smallest counterpart at least. Also, you need to make a correct choice of the type of future Abs. At the moment the attention of the customers are offered fixed and Mobile plant for the production of asphalt mixes. Naturally, the stationary ABZ is more suitable for mass production of mixtures in one particular place. Mobile ABZ is a little inferior to his power, but their main advantage is the possibility of dismantling

[caption id="attachment_265" align="alignleft" width="338" caption="Self Propelled Cranes"][/caption] Self Propelled Cranes are Mobile Cranes mounted on a wheeled chassis and have only one operator position from which the crane is controlled and the vehicle driven. The road speed of this type of crane is generally low usually not exceeding 30km p/h. A variety of self propelled

[caption id="attachment_268" align="alignleft" width="300" caption="Lorry Mounted Cranes"][/caption] Lorry Mounted Cranes -- these Mobile Cranes consist of a lattice or telescopic boom mounted on a specially adapted truck or lorry. They have two operating positions: the lorry being driven from a conventional front cob and the crane being controlled from a different location. The

safe areas; (3) Crane have not been cleared within the barrier; (4) crane and other equipment or a fixed minimum distance a building is in more than 0.5m; (5) the power circuit device is locked or warning signs; (6) whether the requirements of Mobile Crane flat good venue to lay a solid and reliable legs. Third, before driving to a bell or warning alarms; operation close to the person, or a warning should be given intermittent tone. Fourth, during normal operation of the driver shall not

OSHA’s crane standard covers power-operated equipment used in construction that can hoist, lower, and horizontally move a suspended load – including, but not limited to: Articulating knuckle-boom cranes Crawler cranes Derricks Mobile Cranes Tower cranes The standard also applies to crane attachments such as: Augers and drills Clamshell buckets Concrete buckets Hooks Personnel platforms What equipment isn’t covered? Equipment not covered includes: Machinery

and versatile, BossBuyer Gantry Cranes offer cost effective lifting portability that can withstand the heaviest of loads. Easily assembled and disassembled, a BossBuyer Gantry Crane can be used indoors or outdoors, whether mounted or Mobile. Gantries are successfully utilized across multiple industries. BossBuyer Gantry Cranes are available in steel, aluminum or a lightweight model along with adjustable heights and spans. With a BossBuyer Gantry Crane, you can: Easily

Relative Searches

Mobile Crane, Mini Crane Machine, Mini Crane, Mine Crane, Man Crane, Mobile Crane, mobile crane manufacturer, New Crane, Of Tower Crane, Operation Crane,

Email: sales@bossbuyer.com

Skype: bossbuyer

Market Hotline

0086-21-61435-919

Service Hotline:

0086-21-61435-919