Used Crane Search Result

Railroad crane

In an accident, they may leave the tracks. The cranes can pick them up and put them back on the tracks. Railroad cranes can only lift things near the tracks. A railroad crane, (crane car or wrecker (US) or breakdown crane (UK)) is a type of crane Used on a railroad for one of three primary uses: freight handling in goods yards, permanent way (PW) maintenance, and accident recovery work. Although the design differs according to the type of work, the basic configuration is similar in all cases:

Floating crane

Floating cranes are Used mainly in bridge building and port construction, but they are also used for occasional loading and unloading of especially heavy or awkward loads on and off ships. Some floating cranes are mounted on a pontoon, others are specialized crane barges

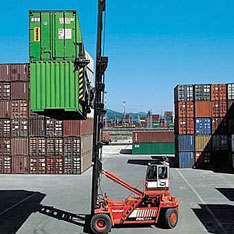

Side lift crane

A side lifter Crane is a road-going truck or semi-trailer, able to hoist and transport ISO standard containers. Container lift is done with parallel crane-like hoists, which can lift a container from the ground or from a railway vehicle.

Stacker crane

A crane with a forklift type mechanism Used in automated (computer controlled) warehouses. The crane moves on a track in an aisle of the warehouse. The fork can be raised or lowered to any of the levels of a storage rack and can be extended into the rack to store and retrieve product. The

Gantry crane

D specifications, which meet the demands of high duty cycles and multiple shift operation, as well as providing decades of reliable service for all applications. Gantry cranes is available in spans to 150 feet and capacities to 150 tons and can be Used either indoors or outside.

Rough terrain crane

Rough terrain crane is a crane mounted on an undercarriage with four rubber tires that is designed for pick-and-carry operations and for off-road and "rough terrain" applications. Outriggers are Used to level and stabilize the crane for hoisting. These telescopic cranes are single-engine machines, with the same engine powering the undercarriage and the crane, similar to a crawler crane. In a rough terrain crane, the engine is usually mounted

Jib crane

A jib Crane is a type of crane where a horizontal member (jib or boom), supporting a moveable hoist, is fixed to a wall or to a floor-mounted pillar, which is a style of cranes in case of which a horizontal portion called the boom or the jib supports a moveable

Loader crane

A loader crane (also called a knuckle-boom crane or articulating crane ) is a hydraulically-powered articulated arm fitted to a truck or trailer, and is Used for loading/unloading the vehicle. The numerous jointed sections can be folded into a small space when the crane is not in use. One or more of the sections may be telescopic. Often the crane will have a degree of automation and be able to unload

Bulk-handling crane

Bulk-handling cranes are designed from the outset to carry a shell grab or bucket, rather than using a hook and a sling. They are Used for bulk cargoes, such as coal, minerals, scrap metal etc.

Telescopic crane

A telescopic crane has a boom that consists of a number of tubes fitted one inside the other. A hydraulic or other powered mechanism extends or retracts the tubes to increase or decrease the total length of the boom. These types of booms are often Used for short term construction projects, rescue jobs, lifting boats in and out of the water, etc. The relative compactness of telescopic booms make them adaptable for many mobile applications.

Tower crane

Tower crane is a modern form of balance crane that consist of the same basic parts. Fixed to the ground on a concrete slab, tower cranes often give the best combination of height and lifting capacity and are Used in the construction of tall buildings. The base is then attached to the mast which gives the crane its height. Further the mast is attached to the slewing unit that allows the crane to rotate. On top of the slewing unit there are three main parts

Truck mounted crane

counterweights for stabilization beyond that provided by the outriggers. Loads suspended directly aft are the most stable, since most of the weight of the crane acts as a counterweight. Factory-calculated charts (or electronic safeguards) are Used by crane operators to determine the maximum safe loads for stationary (outriggered) work as well as (on-rubber) loads and travelling speeds.

port crane

The Port Crane is suitable for heavy work at seaports, river ports and freight yards and it can be equipped with hoisting hooks and grab buckets. Port Crane is applicable to various types of cargos and can be Used for handling containers. The Port Crane is mainly composed by lifting mechanism, rotating mechanism and slewing mechanism. These three mechanisms can work separately or jointly. The single-jib or four-jib Port Crane can be chosen according to different

EOT Crane

The most adaptable and the most widely Used type of power driven crane for indoor service is undoubtedly the three motion Electric Overhead Travelling Crane (EOT crane). It serves a larger area of floor space within its own travelling restrictions than any other permanent type hoisting arrangement.

Cranes

Development depends on infrastructure and infrastructure on heavy machineries. Of all the heavy machines Cranes acquire an important position as they are involved in the building and maintenance of huge projects. Crane machines are the huge tower like machineries having ropes meant to lift or to lower any heavy devices. Hence they are also referred

Tower Crane

A tower crane is Used to build very tall buildings. The crane be on the ground or on a floor in the building. As each floor is built, the crane is moved up. Tower cranes are one of the most important device that is used for the construction of huge buildings. They are

Jib Crane

Jib Crane is another important type of bridge construction machinery. Jib cranes derives their name from the horizontal beam, or jib, upon which the shuttle or hoist is mounted. With horizontal load-supporting boom fastened to a rotating vertical column,

Floating Crane

A floating Crane refers to a type of sea vessel which has a crane mounted on it. In earlier days, floating crane designs were nothing more than old ships transformed to include a huge crane mounted over the deck. Eventually, cataraman, semi-submersible designs

Gantry Crane

Gantry cranes are those cranes which are generally Used for moving heavy loads. They are a common type of portable material handling equipment used in job station or secondary task areas. Gantry cranes are quite similar to overhead cranes except that the bridge which carries trolley is rigidly

FAQ About Used Crane

- Types of Cranes

- Ceiling Mount Articulating Ceiling Type Jib Crane

- Wall/Column Cantilever Mount "I" Beam Jib Crane

- Truck cane standard upperstructure equipment

- Construction and Maintenance of Cranes and Lifting Appliances

- Testing and Examination of Cranes and Certain Lifting Appliances

- Stability of Cranes and Lifting Appliances

- Tower Crane Superstructure

- Tower Crane Safety Devices

- Overhead Crane Inspection

- Cranes, lifting appliances and fork lift trucks

- Brakes, Controls, Derricking Jibs and Cabins for Operators of Cranes

- Crane Lifting Operations - Signalling

- Crane Lifting Operations - Load Not To Exceed Safe Working Load

- Crane Lifting Operations - Secureness of Loads

- Crane History

- Raw Materials of manufacture cranes

- Cranes,overhead traveling crane,Construction cranes,Tower cranes,Mobile cranes,Articulating cranes

- The Manufacturing Process Of Crane

- Crane Safety and Quality Control

- Jib crane motions

- Gantry crane introduce

- News conference addresses concerns over tower crane safety

- Overhead Crane and Bridge Crane

- FACTORS BEHIND THE SELECTION OF CONSTRUCTION EQUIPMENTS

- PORTABLE TRUCK-MOUNTED CRANE BOOMS

- Guy Derrick

- Jacking Towers

- Hydraulic Telescoping Gantries

- Truck Carriers

- All-Terrain Carriers

- Tower-mounted crane

- Crane and Mobile Crane

- Mobile Crane Clearances

- Mobile Crane Clearance In Tight Quarters

- Mobile Crane Ground Support Capacity

- Crane Classification

- Crane Certification

- MOBILE CRANES INTRODUCTION

- A New Approach for Controlling Overhead Traveling Crane Using Rough Controller

- Introduction of overhead crane operator

- Radio Communication Can Assist Container Gantry Crane Operators in Marine Terminals

- What Are Telescopic Cranes?

- Mini crawler cranes

- Popular Construction Equipments or Construction Machineries

- Crane Gantry

- Industrial Cranes

- Gantry Crane or Goliath Crane

- Stainless Steel Jib Cranes

- Jib Cranes

- Articulating Jib Crane

- Floor Mounted Jib Crane

- Crane Steel Structures Test Problems

- Crane Control program analysis and comparison

- Electric Hoist Failure Analysis and Treatment

- Metallurgical cranes on the technical requirements for special work

- Construction Machinery Types and Applications

- Bridge and gantry cranes

- Oregon OSHA’s new crane standard for the construction industry

- Standardization of Jib Crane Design by “F.E.M. Rules” And Parametric Modeling

- Wall Mounted Jib Cranes

- BossBuyer Gantry Cranes

- Bottom-Slewing Tower Cranes Structure and Configuration

- Wind and Tower Cranes

- Gin Pole Derrick

- Active Sway Suppression Techniques of a Gantry Crane System

- Rule about crane brakes and restraints

- YJCrane Gantry Crane

utilisation factors and degree of mobility required. Crane types can range from a simple rope and pulley or gin wheel to a complex tower crane but most can be placed within 1 of 3 groups namely mobile, static and tower cranes. Where Are Cranes Used? Cranes are used all over the world. They build tall skyscrapers in large cities. And, they help farmers in rural areas. Cranes are used near large bodies of water. They load and unload ships. Cranes are built strong to be used anywhere they

from a Gorbel Work Station Bridge Crane to allow the jib to swing under an obstruction or outside the normal coverage of a bridge cranePlatform mounting can deliver the benefits or an articulating jib to multiple work cellsEffortless rotationCan be Used with hook mounted lifting devices (electric, air, or vacuum)

Wall/Column Cantilever Mount "I" Beam Jib Cranes are ideal for heavier loads from 1 to 5 tons (heavier capacities available, contact the factory). They are also available in motorized or manual rotation. Used instead of a wall bracket jib crane when headroom is at a premium.Provide hoist coverage for individual use in bays, along walls or columns, and as supplements to an overhead crane or monorail system.Capacities from 1/4 ton to 5 tons, with spans

planetary reduction gear for precise and smooth swing function. Swing speed (no load) is 2.5 rpm. SWING BRAKE Heavy duty multiple disc swing brake is mechanically actuated from operator’s cab by foot pedal. Brake may be locked on or Used as a momentary brake. An air operated 360º house lock is standard. RATED CAPACITY INDICATOR Rated Capacity Indicator with visual and audible warning system and automatic function disconnects. Pictographic display includes: boom radius,

Cranes and lifting appliances must be of good construction and be properly assembled. This means that they must be of good design which includes, amongst other things, being well built for the purpose for which they are intended to be Used, and be put together properly. The erection and dismantling of cranes and lifting appliances must only be carried out under the supervision of a competent person. This means a person who is fully conversant with the safe and correct

6. The person should:- a) have the requisite knowledge and experiences, both theoretical and practical, of the type of crane or lifting appliance to be tested and examined; to certify with confidence that it is capable of being Used safely and it is free from patent defect and suitable in every way for the duty in which the crane or lifting appliance is to be used. Additionally, the extent of his competency will depend upon the organisation behind him and the technical

Where a crane or a lifting appliance is to be Used on a slope or on uneven or soft ground, precautions must be taken to prevent overturning. This can be done, for example, by reducing the slope, levelling the ground or by using suitable supports. If a situation occurs where a tower

speed 1800 rpm., max. out torque 1100N.m, emission in compliance with European Construction Machinery Stage II. Control System Intelligent computer integrated program control system Is the key technology of the crane. PLC program controller is Used, with combination of conventional electrics, to realize the function of logic control and electronic proportional control of the system, greatly improving safety, reliability and efficiency for crane operation. Crane operation can be shown by

panel lights on, at the same time, load moment limiter stops crane operation. Winch Ratchet Locking Device Winch drum has a ratchet locking device, and it must be turned on when lowering boom, otherwise boom cannot be lowered. The device is Used to stow the boom for safety. Boom Angle Limit When boom angle is more than 800, load moment limiter and hoist limit switch stop boom raising. When boom angle is less than 300, hoist limit switch stops boom lowering. Audio/Video Warning When

on any part of the crane, make sure you have a certified welder and if it is on a structural part of the crane you should get the manufactures procedure. Also, try to determine why it cracked in the first place. Is the crane being overloaded or Used improperly. 3 .Climbing up a and checking the bridge system is normally not part of the daily inspection. Many of these components can be inspected from the ground as the crane is being operated. If something seems wrong, then a closer look would

The Regulations apply to cranes and lifting appliances Used in the manner described in Regulation 2. The terms "cranes" and "lifting appliances" are defined legally in Regulation 1 which deals with the interpretation of various expressions used in the Regulations. "Crane" means:- "An appliance

this is not possible or practicable, steps must be taken to prevent persons from gaining access to the place where they are liable to be trapped. Cabins for Operators of Cranes Where cranes are exposed to the weather, and where they are Used for long periods, a suitable cabin must be provided for the operator which should Protect him from the weather, and Where reasonably practicable, be provided with suitable means of heating Any means provided for heating must not

Where the load is not clearly visible or the hook of the crane or lifting appliance is not clearly visible to the operator, a signaller (banksman) must be Used to transmit the slingers instructions to the operator. All signals must be clear and concise and should, if they are visual signals, conform to the recognised code of manual signals. The operator must take notice of only the signals of

excavator bucket sizes are determined by the capacity of the machine. This naturally limits the load which these machines can carry. The possibility of overturning is not as easily achieved as that on conventional cranes, when the machine is being Used as an excavator.

do not become displaced during lifting operations.Some loads are assembled with securing straps which are only designed to hold the load together, for example bricks and packaged materials. In these circumstances the securing straps must not be Used to connect the load to the crane or lifting appliance unless the strap is especially designed for this purpose, for example, man made fibre slings used for handlingcement cargos.

that lift and move bulk materials, such as grain and coal, in a continuous process. The word crane is taken from the fact that these machines have a shape similar to that of the tall, long-necked bird of the same name. Human beings have Used a wide variety of devices to lift heavy objects since ancient times. One of the earliest versions of the crane to be developed was the shaduf, first used to move water in Egypt about four thousand years ago. The shaduf consists of a long, pivoting

The most important substance Used to manufacture cranes is steel. Steel is an alloy of iron and a small amount of carbon. For structures that do not require very high strength, a common form of steel known as carbon steel is used. By definition, carbon steel contains less than

Very few machines exist in as wide a variety of designs as cranes. Before the crane is constructed, the manufacturer must consider the site where it will be Used and the weight it will need to lift. In addition, cranes are often modified to suit the needs of the user. For these reasons, it is not much of an exaggeration to say that no two cranes are exactly alike. Cranes used for industrial purposes

thick-walled iron molds, where it cools into ingots.In order to form flat products such as plates and sheets, or long products such as bars and rods, ingots are shaped between large rollers under enormous pressure. Hollow tubes, such as those Used to form the latticed booms of large cranes, may be made by bending sheets of steel and welding the long sides together. They may also be made by piercing steel rods with a rotating steel cone. The cables used to lift weights are made from steel

Safety is the most important factor to be considered during crane manufacturing. The steel Used to make the crane is inspected to ensure that it has no structural flaws that would weaken the crane. Welds and bolts joints are inspected as well. The United States government sets specific regulations through the Occupational Safety and

Jib crane have the following motions: Hoisting motion Derricking or luffing motion Slewing motion Long travel motion Hoisting motion: It is Used to lift or lower the load. This is usually achieved by steel wire ropes being affixed to a crane hook or a grab hanging from the outer end of the jib. The rope is applied through some receiving arrangement and controlled and operated by a winch

Gantry crane is installed in the level of bridge constitute the two legs supporting the shape of a gantry-type crane bridge. This crane orbit on the ground, mainly Used in open yard storage, shipyards, power plants, ports and railway stations to carry out cargo handling and installation. Gantry cranes lifting bodies, car bodies and bridge operation structure, with essentially the same bridge crane. As a result

“but the tragic loss of life is particularly troubling and completely unacceptable.†He noted how important of a role cranes play in our society, and how tower cranes are a “reliable technology†and have been Used since the 1940s in construction projects. “Of the more than 3,000 tower cranes in North America, about 2,100 are in use on any given day,†said Dandrea. “With a conservative estimate of 50 lifts daily per crane, more

system. Onemore advantage will be the hoist so as to lift the objects and the bridge that spans the area covered by the crane, together with atrolley so as to move along the bridge. Overhead Crane Application Overhead cranes are most generally Used within the steel business. The steel is dealt with making use of this particular crane ateach stage of the manufacturing procedure until the product is delivered from the factory. The crane is even responsible forpouring raw materials into a furnace

and for lift planning (Meehan 2005). Examples are Compu-Cranc and LPS (NCI 2006). Cranimation and Tower-Management (Cranimax 2006), LiftPlanner (LiftPlanner Software 2006) and MethoCAD (Progistik 2006). These software packages, commonly Used by engineering and construction firms, address mainly the technical aspects of crane location and lift planning. In the following paragraphs, we discuss some of the factors that govern the equipment-selection decision. It may be difficult

10-20 tons, at the most. The truck-mounted crane booms are removable from the truck beds on which they are mounted. There are two forms of this portable type of equip- ment. One is the articulated, short height knuckleboom, which is frequently Used to load material on and off the truck. They operate somewhat like the human arm with hydraulic controls to make the movements from the "shoulder" at the truck bed through the "elbow" to the "wrist" and "hand" at the load pick up end. This type of

Guy derricks at one time were the only practical means to erect steelwork on high-rise structures, but that work is mostly done now with tower cranes. Guy derricks may also be Used for general rigging, stone quarrying, and construction of refineries and chemical plants. A guy derrick can be described as a Chicago boom with its own integral column, called a mast, held vertical by six or more guy ropes, as shown in Figure

Jacking towers are Used primarily for vertical movement of large loads in tight quarters or out-of-the-way locations where a large crane may not be suitable. There are two well-established types: those which push the loads up can be called push-jack systems, and others

Telescophig gantries are typically Used for heavy lifting where mobile cranes or derricks are not feasible, where classic "jack and slide" procedures are awkward, or where other conditions make use of the gantry the most economical means to perform the work required. These systems first

Truck-type crane carriers should not be confUsed with ordinary commercial truck chassis. A crane carrier is designed and built for no other purpose than crane service. Figure 2.13 shows a carrier for a 300-ton model. It is still clear that this chassis is quite different from that of a standard

First appearing in Europe during the late 1970s, the all-terrain crane now accounts for a majority of mobile-crane sales throughout the world. The carriers Used on these telescoping cantilevered-boom machines combine the high road speeds of truck carriers with some of the off-road capabilities of the rough-terrain crane. Large-capacity multiaxle models have appeared featuring the characteristics necessary

At least that is the broad picture; contractors in some localities cling longer to traditional practices than others. Tower cranes are the lifting machines of choice worldwide for most mid- and high-rise building construction. They are Used also on expansive sites where the broad hook sweep and the relative ease of coordinating multiple tower cranes is an advantage. There are niche markets for these as well; cable stay and suspension bridges, offshore oil platforms, and power

to the barnstormers and bush pilots who pushed their rudimentary craft to the limits with hardly a thought for risk. Likewise, crane operation was once a seat-of-the-pants skill governed largely by the notion that lifting equipment could be Used right up to the point of tipping over. Both cranes and aircraft of early vintage were machines with modest capabilities that responded almost like extensions of the operators themselves. Machines were relatively small and inexpensive, and pilots

of a building, the underside of the boom or jib cannot clear it. The authors refer to this as a swing clearance problem. The hook cannot reach sufficient height to place the load. This is known as a drift deficiency. It is sometimes caUsed by an underestimation of the length slings or height of the rigging supporting the load. The aft end of the crane superstructure cannot clear an obstruction. The counterweights, for instance, interfere with a tree or a live mast fouls a

These limitations not only weigh on the operation but also need to be considered when the front-end attach ment is to be stowed during nonworking hours or the crane is to be secured in advance of a storm. Interference is sometimes caUsed by a secondary element that might easily be missed unless the planner takes a second look. A cab, slack cable, or transition piece might easily be overlooked. The clearance dimensions of projecting or overhanging components are usually given

Presumptive soil-bearing capacities Used for building foundation design are often conservative when applied to crane supports. Buildings present long-term loads to the ground, so that allowable soil capacity must reflect a degree of long-term settlement control not necessary for

covers cranes where precise handling of equipment at slow speeds with long idle periods between lifts are required. Capacity loads may be handled for initial installation of equipment and for infrequent maintenance. Typical examples are cranes Used in powerhouses, public utilities, turbine rooms, motor rooms, and transformer stations. This is the lightest crane as far as duty cycle is concerned. Class B (Light Service): This service class covers cranes where service requirements are light

What is crane certification? How often does a crane have to be certified? Who can certify a crane and just what is involved? Good questions. Lets start with exploring just what crane certification is. Aside from cranes Used in the maritime industry, "crane certification" doesn't really mean a whole lot. At best, it merely serves to satisfy the normal record keeping requirements of OSHA, which should not be confused with "crane certification". But wait a minute! There

capacity of models usually purchased for industrial use ranges from 5 to 30 tonnes. The radius of operation depends, of course, on the length of the boom. Auto-lift models with booms up to 18 m long are standard. Boom up to 30 m long are Used on special work. The group of trackless cranes is made up mainly of pillar cranes mounted on trucks, automobiles or tractors and intended for traveling on dirt, gravel and asphalt roads.

The results of a simulation comparing the performance of both controllers are shown. From these results we infer that the performance of the proposed rough controller is satisfactory. The crane can be considered as one of the most important tools Used in industry to transfer loads from one desired position to another. Usually cranes have very strong structures in order to lift heavy payloads in factories, in building construction, on ships, and in harbors. Until recently, cranes were manually

This study identified the knowledge and skills necessary for safe crane operations. A representative number of crane operators then validated that the knowledge recommended by the experts was vital to safe operations. The study and survey were then Used to generate the test blueprints and content specifications. Development of the Overhead Crane Operator Written Examination involved a panel of crane operation content experts who worked with the staff of International Assessment Institute to write

to use to ensure that the transmission is clear and reliable. Each crane should use a separate channel, if frequencies are available. The operator’s radio should be equipped with a hands-free system. Radios should not be Used for personal communication or discussions not related to the operation at hand. Make sure that the crane operator and other ground personnel communicating with the crane operator have been trained on how to properly use the radio equipment.

Telescopic cranes are another form of heavy cranes employed to transport and maneuver objects from one place to another. Cranes like the telescopic cranes are often Used in day-to-day hauling operations but it has also to be noted that these heavy cranes are very important when it comes to carrying out maneuvering operations in ports as well. Telescopic cranes are mobile in the sense that they transport goods

The low overall operating weight, compact dimensions and alternative power sources allow the cranes to access sites other cranes simply would not be suitable for. The cranes low headroom allows them to be Used indoors or even underground. The powerful rubber tracked CX-8T with 360 degrees slew and 4 stage telescopic boom, lifts 8 tonnes, yet occupies a footprint of only 3.48 x 3.48 metres. The compact

There is a range of construction machineries or equipments, ranging from the very heavy machines to the light, portable and mobile equipment. We present below some of the most popularly Used construction equipment used for construction purpose. [caption id="attachment_149" align="alignleft" width="315" caption="Construction equipments and machineries"][/caption] Backhoe loader: This is an equipment with a front bucket / shovel.

A crane, which is equipped with a derrick or tower, is Used to lower and lift materials with the use of pulleys and cable. Heavy equipment manufacturers and the construction industry use cranes in various activities connected with their process. Cranes used in the construction industry are mostly temporary

although it is second hand, here are some tips on how to buy used deck cranes for your yacht: Take note of the performance. Make sure that the crane is not yet hard to manipulate. Consider the lifting capacity and the speed of the lifting. Used Cranes are expected to have lower performance but with proper care, the utmost performance can be restored. Consider the span of the arm of the crane. Make sure that as you install it in your yacht and made use of it, your yacht will not topple

Our range of gantry and goliath crane can be Used for both indoor and outdoor purposes. Fabricated using quality raw material our range is safe to operate and designed as per IS standard. Our Gantry and Goliath Crane Features: [caption id="attachment_191" align="alignright" width="243"

contamination in processing environments Safely handle oversized loads in sanitary environments Reduce crane corrosion over surface finishing and metal treatment tanks Clean overhead lifting equipment with the same compounds Used on other wash-down processing equipment Service mixers, pumps and motors on-site with integrated jib cranes without other non-sanitary equipment

ones that can swing through an angle or arc are more useful since they can operate over larger areas as compared to the ones that remain stationary. Nowadays crane jibs have almost become an indispensible part of a worker’s life. They are Used to serve a multitude of purposes besides being utilized for a variety of applications in docks, ship yards, sites for building construction, ware houses, factories, etc. This multi-utility equipment comes in different types and is grouped

the center of the horizontal section that lifts the load. This feature enables the user to bend or fold the arm if required. Since it can be folded, articulating jib cranes are easy to maneuver in small areas with space restrictions. Mostly Used in warehouses, large departmental stores and in the food industry, to name a few, articulating jib cranes are excellent equipments for lifting heavy loads in confined and small spaces. However, the articulating jib crane has its share of

the floor. They generally come with a foundation base that needs to be fitted with the ground in order to keep the equipment standing upright and also help it to support itself. In terms of expenses, this is the most economical crane to be Used but it requires a lot of space to function properly. Considered as one of the most efficient machines, floor mounted jib cranes can rotate through 360 degrees.

Currently, the steel plant are widely Used in plant construction. Because of its short construction period, construction process is relatively simple, low cost and other advantages, except for some special occasions, the steel plant is always given priority. And installation of the cranes

In recent years, updating and development of bridge crane in order to improve crane performance as the main indicator, the speed of which the most prominent crane. The following are several commonly Used to speed the program cranes were analyzed and compared. 1. Speed ??rotor resistance (1) cam controller to control the rotor resistance asymmetry of the program used for 5 ~ 10t bridge crane of the main control circuit common, through the tandem

abnormal noise from the gear issue, gear failure (such as lack of gearbox or bearing oil, gear wear or damage, bearing damage, etc.), then should stop to check, first determine the reducer or gear box bearings added prior to use oil, whether Used oil changed regularly, such as lubrication is not required, will not only produce high gear, "buzzing" sound, but also excessive wear or damage to the gears and bearings. Some people think that without a temporary or casual gear add a little oil,

AQSIQ "quality to do special ?2007? 375" document, published in the use of non-metallurgical crane for lifting the molten metal in the remediation requirements, as follows, for everybody to learn, discuss and exchange. (A) has been Used for general overhead crane lifting molten metal, shall be replaced in order to comply B/T7688.15-1999 "Metallurgical ladle crane technical conditions" requirement of the casting crane. If the plant, based on such factors as the conditions do not

Construction machinery refers to the mechanism Used in the project construction. It is widely used in construction, water conservancy, electric power, roads, mines, ports and national defense sectors etc. Generally speaking, all earthwork construction projects, road construction and maintenance,

crane bridge or remotely from the ground, either through a hard-wired pendant control or radio control. The major components of bridge and gantry cranes are: • the runways • the bridge • the hoist unit • the crab or hoist trolley Used to transverse the load • the winch drum and hoist rope • the rope termination points, the hook and hook block, which may contain one or more sheaves • the braking systems • the ‘crane operating area’ • the electrical supply and

applies to all employers who are engaged in construction work and use cranes or derricks for construction. The standard takes effect Feb. 9, 2011. What equipment is covered? Oregon OSHA’s crane standard covers power-operated equipment Used in construction that can hoist, lower, and horizontally move a suspended load – including, but not limited to: Articulating knuckle-boom cranes Crawler cranes Derricks Mobile cranes Tower cranes The standard also applies to crane

of its widespread use and established popularity among the jib crane manufacturers. Access to the "F. E. M. Rules" from any design procedure is fully automated by using a systematic approach of parametric modeling. The parametric model can be Used for various jib crane design cases as well as further for optimization. Jib Cranes are industrial machines that are mainly used for materials movements in construction sites, production halls, assembly lines, storage areas, power stations and

components supplied by BossBuyer. All hardware for bolting the hinges to the jib crane is supplied. 301 Series Wall Mounted Jib Cranes - Tie Rod Supported 200° rotation. Wall bracket (tie rod supported boom). No supporting components are Used under boom enabling full utilization of work area. Utilizes standard I-beam and single tie rod design to eliminate off-center loading problems. Spans to 30 feet standard (longer spans available). This design is the most economical style of

Dependable and versatile, BossBuyer Gantry Cranes offer cost effective lifting portability that can withstand the heaviest of loads. Easily assembled and disassembled, a BossBuyer Gantry Crane can be Used indoors or outdoors, whether mounted or mobile. Gantries are successfully utilized across multiple industries. BossBuyer Gantry Cranes are available in steel, aluminum or a lightweight model along with adjustable heights

to connect between the ground or any other supporting surface and the slewing crane. The undercarriage is commonly either sta- tionary (Figures 19.16a and Figure 19.17b) or rail-mounted. Light models may have a wheeled undercarriage, but this is Used only for infrequent crane relocations on the jobsite, without loads, and not for operation. In truck-mounted tower cranes (see below), the truck replaces the conven- tional undercarriage. Another configuration, seen mainly in Europe, is that of a

winds. In the United States, these regions are on the Atlantic, Gulf, and Northwest coasts as well as some river valleys and mountain passes. Installation practices should be adjusted for those regions. A heavier mast and foundation might be Used or the freestanding height reduced. Alternately, a contingency plan to guy, brace, or remove the crane might be considered. When in the midst of climbing, a tower crane is in a balanced stance that may be particularly sensitive to disturbance

from one another. In the middle range alternative lifting devices are more practical, and so middle-sized poles are a rarity. Long heavy-duty gin poles operate at fixed radii with a lean of only 50 or 100 from the vertical. They are primarily Used for rigging work, raising heavy machinery, vessels, or structural components into place. Poles of 250 ft (76 m) or more are available with capacities ranging to about 300 tons (270 t). The practical limit to the size results from the need to use

Research on the control methods that will eliminate sway angle of gantry crane systems has found a great deal of interest for many years. Active sway angle control of gantry crane consists of artificially generating sources that absorb the energy caUsed by the unwanted sway angle of the rope in order to cancel or reduce their effect on the overall system. Lueg in 1930 (Lueg, 1930), is among the first who used active vibration control in order to cancel noise vibration. The requirement of precise

within a distance, in feet, equal to 10% of the full load speed in feet per minute when traveling at full speed with full load. (2) A trolley of a crane shall meet the requirements of subrule (1) of this rule. (3) A crane that is being Used out-of-doors shall have a positive mechanical restraint, such as, but not limited to, an automatic rail clamp, to secure the crane against wind movement while parked. If clamps act on the rail heads, beads or weld flash on the rail heads shall be

operators platform is a stand-up version with excellent visibility, and we offer wireless remote control as an option. Superior manufacturing and service. How we build them is why they perform so well. At YJCrane, the attention to detail Used when building our machines shows in our finished product. Each of our employees gives the utmost care to building our equipment and our quality control department is always looking out for our customers by discriminating against the slightest defects.

Relative Searches

Used Crane, Used Boom Crane, Truck Mounted Crane, Truck Crane P H, Trolley Crane, Used Crane, Used Truck Crane, Van Crane, Vehicle Crane, Wheel Crane,

Email: sales@bossbuyer.com

Skype: bossbuyer

Market Hotline

0086-21-61435-919

Service Hotline:

0086-21-61435-919