Hoist Crane Search Result

Overhead crane

Also known as a 'suspended crane', an overhead crane works very similar to a gantry crane but instead of the whole crane moving, only the Hoist / trolley assembly moves in one direction along one or two fixed beams, often mounted along the side walls or on elevated columns in the assembly area of factory. Some of these cranes can lift very heavy loads.

Side lift crane

A side lifter crane is a road-going truck or semi-trailer, able to Hoist and transport ISO standard containers. Container lift is done with parallel crane-like hoists, which can lift a container from the ground or from a railway vehicle.

Rough terrain crane

Rough terrain crane is a crane mounted on an undercarriage with four rubber tires that is designed for pick-and-carry operations and for off-road and "rough terrain" applications. Outriggers are used to level and stabilize the crane for Hoisting. These telescopic cranes are single-engine machines, with the same engine powering the undercarriage and the crane, similar to a crawler crane. In a rough terrain crane, the engine is usually mounted in the undercarriage rather than in the upper,

Jib crane

A jib crane is a type of crane where a horizontal member (jib or boom), supporting a moveable Hoist, is fixed to a wall or to a floor-mounted pillar, which is a style of cranes in case of which a horizontal portion called the boom or the jib supports a moveable hoist and is generally attached firmly to a wall or a pillar fixed to the floor. This

Bridge Crane

A bridge crane runs on an elevated runway system along the length of a factory and provides three axis of hook motion (X, Y, and Z). The Hoist moves the load up and down, the trolley moves the load right and left, and the bridge of the crane moves the load forward and backward. Both single and double girder overhead traveling bridge crane designs allow very precise hook positioning and

All Terrain Crane

As the name suggests, all-terrain Cranes can manoeuvre through rough terrain as well as public roads with ease. These cranes are technologically the most advanced of all the mobile cranes. They come in both lattice-type and telescopic-type boom options. All terrain cranes that are ideal

Truck mounted crane

able to travel on highways, eliminating the need for special equipment to transport the crane. When working on the jobsite, outriggers are extended horizontally from the chassis then vertically to level and stabilize the crane while stationary and Hoisting. Many truck cranes have slow-travelling capability (a few miles per hour) while suspending a load. Great care must be taken not to swing the load sideways from the direction of travel, as most anti-tipping stability then lies in the stiffness

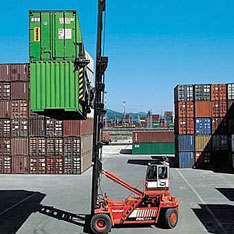

port crane

The Port Crane is suitable for heavy work at seaports, river ports and freight yards and it can be equipped with Hoisting hooks and grab buckets. Port Crane is applicable to various types of cargos and can be used for handling containers. The Port Crane is mainly composed by lifting mechanism, rotating mechanism and slewing mechanism. These three mechanisms can

EOT Crane

widely used type of power driven crane for indoor service is undoubtedly the three motion Electric Overhead Travelling Crane (EOT crane). It serves a larger area of floor space within its own travelling restrictions than any other permanent type Hoisting arrangement. As the name implies, this type of crane is provided with movement above the floor level. Hence it occupies no floor space and this can never interface with any movement of the work being carried out at the floor of the building.

Cranes

Development depends on infrastructure and infrastructure on heavy machineries. Of all the heavy machines Cranes acquire an important position as they are involved in the building and maintenance of huge projects. Crane machines are the huge tower like machineries having ropes meant to lift or to lower any heavy devices. Hence they are also referred

Truck Concrete Pumps

Truck mounted concrete pumps are those engineering products that are used to supply concrete to places which are difficult to reach by other heavy machines. Concrete Pumping Equipment required : concrete pump, heavy-duty pipe, hose and other accessories. Concrete pumps can be mounted on any type of diesel powered trucks. When pressure is applied to a column of fresh concrete by the concrete pump it forces the concrete through a lubricated pipe.

Bridge Crane

to build or fix a bridge. It operates on two tracks and has four way horizontal movement. Bridge cranes cover rectangular area and can be floor supported or hung from the ceiling. The main components of bridge cranes are bridge, trolley, Hoist drum, hoist cable, hoist block, hook bumpers, pendant and limit switches. On-off switch is on control pendant for taking emergency steps, in the event of failure of any of the control panels.

Jib Crane

Jib crane is another important type of bridge construction machinery. Jib cranes derives their name from the horizontal beam, or jib, upon which the shuttle or Hoist is mounted. With horizontal load-supporting boom fastened to a rotating vertical column, jib crane is either attached to a wall or extending from floor to ceiling.

FAQ About Hoist Crane

- Wall/Column Cantilever Mount "I" Beam Jib Crane

- Truck Crane Boom Equipment

- Truck Crane Hydraulic System

- Tower Crane Safety Devices

- Safe Crane Operations

- Brakes, Controls, Derricking Jibs and Cabins for Operators of Cranes

- Crane History

- Jib crane motions

- lifting crab of a EOT crane

- WALKING CRANE FOR OPERATION BY POWER OR HAND

- Overhead Crane and Bridge Crane

- Cranes and hoists operating rules

- Double Legged Gantry Cranes

- PORTABLE TRUCK-MOUNTED CRANE BOOMS

- Tower-mounted crane

- Mobile Crane Clearance In Tight Quarters

- Single Girder Overhead Cranes and Double Girder Overhead Cranes

- CABLE CRANES

- MOBILE CRANES INTRODUCTION

- Crane accessories and auxiliary equipment

- Crane & Hoist Safety Responsibilities

- Crane Rigging a Load and Crane Overloading

- Material Handling Solutions

- Introduction of overhead crane operator

- Radio Communication Can Assist Container Gantry Crane Operators in Marine Terminals

- Tower Crane

- Self-Raising Tower Crane

- Tower cranes

- Single Girder Overhead Traveling Cranes

- Industrial Cranes

- Double Girder Overhead Traveling Cranes

- Gantry Crane or Goliath Crane

- Tower Crane For Sale

- Wall Bracket Jib Crane

- Jib Cranes

- Portable Jib Crane

- Crane Control program analysis and comparison

- Electric Hoist Failure Analysis and Treatment

- Metallurgical cranes on the technical requirements for special work

- General requirements of the safe operation of crane drivers

- Customer Order cranes should know a few basic parameters

- Crane Preventive Maintenance Checklist

- Bridge and gantry cranes

- Crawler Crane QUY50

- Oregon OSHA’s new crane standard for the construction industry

- Crane Component

- BossBuyer Jib Cranes

- Rotary and Rectilinear Cranes

- Electric Overhead Travelling Crane (EOT Crane) Parts

- Workstation Jib Cranes

- Articulating Jib Cranes

- Single-girder overhead travelling cranes with the new Demag DR rope hoist

- Active Sway Suppression Techniques of a Gantry Crane System

- Rule about marking rated capacity of crane

- YJCrane Gantry Crane

ideal for heavier loads from 1 to 5 tons (heavier capacities available, contact the factory). They are also available in motorized or manual rotation. Used instead of a wall bracket jib crane when headroom is at a premium.Provide Hoist coverage for individual use in bays, along walls or columns, and as supplements to an overhead crane or monorail system.Capacities from 1/4 ton to 5 tons, with spans up to 20 ft.Utilize I-beam boom assemblies for heavier capacities and longer

consists of a single telescope cylinder and high strength leaf chains to extend and retract the third and tip sections. High-strength four- plate construction with embossed side plate holes reduces weight and increases strength. A single boom Hoist cylinder provides for boom elevation of -4 to 78 degrees. Max tip height is 133’ (40.54 m).BOOM HEADWelded to outer section of boom. Five or six load sheaves and two idler sheaves are made of nylon and mounted on heavy- duty antifriction

PTOs. A separate steering pump is driven directly from the engine. Combined system capacity is 131 gpm (495 Ipm). Remote hydraulic oil cooler is standard. Main Winch Pump 57.3 gpm (216.9 Ipm) @ 4,500 psi (316.4 kg/cm2) Boom Hoist and Telescope Pump 42.6 gpm (161.3 Ipm) @ 4,500 psi (316.4 kg/cm2) Outrigger and Swing Pump 21.2 gpm (80.3 Ipm) @ 3,500 psi (246.1 kg/cm2) Power Steering Pump 8 gpm (30.3 lpm) @ 1900 psi (133.0 kg/cm2) FILTRATION Full

Tower crane safety devices comprise: load moment limiter, turntable lock pin, boom backstop, Hoist limit switch, anemometer, level gauge, hydraulic overflow valve, counterbalance valve, two-way hydraulic lock, stewing warning lamp and travel warning lamp, etc. Load Moment Limiter Detection function: automatically detect boom angle and lifting

sourcesIf an estimate of the load is near the max. capacity of the crane, then use a dynamometer to measure the exact weightUse a loud signal, such as a whistle, horn or bell or verbal warning to alert employees of crane movementNever Hoist a load over the heads of employeesNever use limit switches or end stops as operating controlsBegin each shift by testing the upper limit switches Avoid running the crane into the end stops or limit switches Never walk backward when guiding a load

practicable controls should be so arranged that inadvertent operation can be prevented. Cranes with Derricking Jibs Cranes, fitted with derricking jibs, which are driven through a clutch from the same source of power which drives the Hoisting mechanism, must be fitted with an interlocking arrangement which prevents the free fall of the jib when the derricking clutch is disengaged. Precautions where Crane or Lifting Appliance has Travelling Slewing Motion Precautions must

A crane is a machine that is capable of raising and lowering heavy objects and moving them horizontally. Cranes are distinguished from Hoists, which can lift objects but that cannot move them sideways. Cranes are also distinguished from conveyors, that lift and move bulk materials, such as grain and coal, in a continuous process. The word crane is taken from the fact that these

Jib crane have the following motions: Hoisting motion Derricking or luffing motion Slewing motion Long travel motion Hoisting motion: It is used to lift or lower the load. This is usually achieved by steel wire ropes being affixed to a crane hook or a grab hanging from the

The lifting crab of a EOT crane is an independent two motion machine and consists of the Hoist machinery built on to a frame, which is mounted on runner wheels, and driven by a motor through suitable gearing. The crab is also known as trolley. Various designs of crabs, arranged with C.I. side frames, mild steel side frames are in use.

Fig. 52 represents a walking crane operated by power and consisting of a boom, rotating around a fixed column mounted upon an extended truck, which latter travels upon a suitable rail upon the floor. Power is utilized for Hoisting and lowering, and for propelling the crane longitudinally upon its track. Cranes of this type are built of any desired capacity from r to io tons, and for operation either by hand or by power. The base consists of two wrought iron girders united

Overhead Crane Main Parts Overhead cranes normally have either double beam or one beam construction. These are made out of more complex girders ornormal steel. The single bridge box girder crane is complete together with the system and the Hoist and is operated making use ofa control pendant. If the application needs heavier capacity systems for at least ten tons, double girder bridge cranes are normallyutilized. With the girder box configuration, one major benefit is the lower deadweight

Crane operators shall comply with the following rules while operating the cranes and Hoists: Do not engage in any practice that will divert your attention while operating the crane. Respond to signals only from the person who is directing the lift, or any appointed signal person. Obey a stop signal at all times, no matter

Double Legged Single Girder 5 1 Wallace, 12' 0", Tri-Adjustable Semi-Gantry Cranes for Sale Semi-Gantry (P&H) Single Girder, TR 5 2 30'-0" Span, 20'-0" Lift, 460V, P&H Hoists Semi-Gantry (P&H) Single Girder, TR 10 2 30'-0" Span, 20'-0" Lift, 460V, P&H Hoists Crane Bridges Only for Sale Bridge Only-No Hoist Double Girder, TR 10 1

on the truck for travel to the place where the material would be unloaded for the construction. A truck crane is designed for a more permanently attached boom and does not have much flat platform area to carry materials. That type of lifting and Hoisting equipment is considered and discussed as a mobile crane in the next section.

the pitfall of premature fatigue failure. With the exception of a few diesel-powered machines with hydrostatic drives, tower cranes are powered by electricity and motors driving all the machinery are almost universally electric, too. The Hoist motors on older machines have high- and low-speed ranges with stepped increments in each range. More recent models have variable- frequency drive or other forms of continuously adjustable speed motors with friction or eddy-current brakes and

working radius. While the boom or jib might have clear space to swing from the pickup location to the load setting zone, the minimum radius prevents loads from being placed close to the crane. A luffing jib might be fitted with a mid fall Hoist line to overcome this inadequacy. The tail-swing radius may encroach over an active traffic lane or face interference from an obstruction. A large crane can have a rear projecting gantry, strut, backstays, or a live mast capable of fouling

Span Range 3 meters to 30 meters Description of single girder overhead cranes Single girder dual motor cranes provide greater floor coverage than other type cranes. The close crane end approaches coupled with a close trolley approach Hoist give you more working floor coverage This can reduce space requirements in new buildings, or expand your usable space in existing buildings. Adjustable torque magnetic disc/shoe brake for smooth operation. Forged steel crane wheels for long

over parallel tracks. Specifications of Cable Crane Spans range between 1,000 and 4,000 m. But 10,000 m. spans are also met with. Standard capacity is 1 to 25 tonne while cableways rated at 150-tonne capacity arc also in use. The load Hoisting speed is 1.5 to 0.9 m per second depending on the height and the conveying speed varies between 8 to 12 m/sec. Towers are spotted into the working position at a rate of 6 tc 25 m/min. Applications of Cable Crane Storage and production

mounted (c) Rail mounted locomotive (d) Floating cranes (e) Sky cranes Mobile crane (power driven) includes all type of traveling jib cranes, such as truck mounted, crawler mounted, and locomotive crane on rails.Mobile cranes are Hoisting devices mounted on rubber tyred trucks, rollers or railroad wheels. Most of these cranes are full-rotating. Their mountings make them a distinctive group. Truck, crawler and locomotive cranes have now been highly developed for industrial

provide for favorable travel characteristics and minimum crane runway wear Infi nitely stepless variable travel speeds via frequency inverters with speeds up to 240 fpm guarantee travel with minimum load-sway as well as precise positioning Hoist trolleys State-of-the-art Demag DR rope hoist of C-shaped design optimized for crane applications with higher hoist and cross travel speeds provides higher handling rates and effi ciency for cranes with capacities up to 50 m t Compact designs

Supervisors are responsible for: Ensuring that employees under their supervision receive the required training and are certified and licensed to operate the cranes and Hoists in their areas. Providing training for prospective crane and hoist operators. This training must be conducted by a qualified, designated instructor who is a licensed crane and hoist operator and a full-time [COMPANY] employee. Evaluating

Make sure that shackle pins and shouldered eye bolts are installed in accordance with the manufacturer's recommendations. Make sure that ordinary (shoulderless) eye bolts are threaded in at least 1.5 times the bolt diameter. Use safety Hoist rings (swivel eyes) as a preferred substitute for eye bolts wherever possible. Pad sharp edges to protect slings. Remember that machinery foundations or angle-iron edges may not feel sharp to the touch but could cut into rigging when under several

easy to position and easy to operate. This helps reduce injuries and increase productivity. 6. Versatility YJM makes a complete line of crane systems to meet your individual needs. 7. Safety All cranes are pre-engineered for powered Hoist operation-with a factor of 15% of the jib capacity for the combined weight of the hoist and trolley and an additional factor of 25% of the jib capacity for the impact of powered hoists. 8. If It's Late, We Pay the Freight When delivery is

of the following overhead crane types: Cab-operated Pendant/remote control All overhead (bridge) and gantry cranes that meet the requirements of the ASME B30.2, B30.11, B30.16, and/or B30.17 standards and have powered functions for Hoist, bridge, and trolley are covered by CCO certification exams. Note that the NCCCO Exam Management Committee draws questions from the ASME B30.2 standard for Overhead and Gantry Cranes in an effort to lessen the burden on candidates preparing to

using hand signals recognized at the port. However, during non-routine tasks or in an emergency, employees may need more interactive communication with the crane operator. Non-routine tasks include handling oversized or unusually shaped cargo, Hoisting personnel, and handling damaged containers or jammed twist- locks. Emergency situations can occur when one employee sees another employee beneath a load, or when a container is not properly disconnected from a chassis, resulting in accidental

[caption id="attachment_38" align="alignleft" width="360" caption="tower crane"][/caption] Tower Crane Key Specification · Square shaped structure of steel tube · Mian color: yellow · Function: Hoisting · Attached devices: generator, reducer, driver cab, cable, counterweight · Certificates awarded: CQM, CE, TS, ISO9001:2000 · A-grade 315TM Certificate for producing, installation, rectification, and maintenance of tower crane issued

Experience In This Area · 800 Staffs · Version: fixed or traveling type · Free height: from 60meters · Max. height: 200meters · Max. radius: 70meters · Jib end load: 3MT at70 meters · Max. load: 12MT at 22meters · Hoisting mechanism system: 1 · Drum capacity: 400meters · Slewing mechanism system: 1 · Slewing speed: 0.6r/min · Trolley mechanism system:1 · Power line voltage: 380V/50Hz · Color: yellow · Counter weight: (without concrete) ·

system adopts domestic fine quality or import components,performance is stable and reliable. Mast section, tie bar, upper and lower bracket and so on, main parts all adopt CO2, GSAW with large in weld penetration, small in transformative. Hoisting mechanism has good timing performance, rise and fall are stable, shockless. Swing mechanism adopts winding motor or frequent motor, operating balance, efficient, fast and convenient in position.

align="alignright" width="241" caption="Single Girder Overhead Traveling Cranes"][/caption] Some of the features of our Single Girder Overhead Traveling Cranes are Modern design Safe operation as per IS 807 / 3177 and Hoist IS 3938 Capacity - 0.5 ton to 20 ton Span - 3Mtrs to 35Mtrs and above Hoist - Ace wire rope Hoist with Motorized Trolley Speed - Single speed or dual speed for Hoisting, Cross travel and long Travel with variable Speeds. If

toppling over when used. The deck cranes that are needed for a yacht may require the said minimum specs since yachts do not perform heavy lifting as compared to big boats and ships. Deck cranes for your yacht will not just be used for pleasure Hoisting and the like. It can most serve and help you during emergency purposes. There are many things that a deck crane installed in a yacht can do. For instance, you can use it for lifting heavy diving equipment and load it in the yacht. Used deck

Fabricated as per the latest industry standards, our range of double girder overhead traveling cranes is available in both single and dual speed for Hoisting, cross travel and long travel. Safe to operate, it possesses all the modern operational controls. Some of the features of our Double Girder Overhead Traveling Cranes are as follows: [caption id="attachment_183" align="alignright" width="239"

Features: [caption id="attachment_191" align="alignright" width="243" caption="Gantry crane / Goliath crane "][/caption] Heavy and Light duty Indoor and Outdoor purpose Efficient and Safe Operation As per Is 807 and 3177 and Hoist as per IS ¿ 3938 Capacity - 0.5 Ton to 50 Tons Span - 5 Meters to 30 Meters Over Hang if required If you are interested in our Gantry Cranes or Goliath Cranes, please email to us : sales@bossbuyer.com.

· Square shaped structure of steel tube · Mian color: yellow · Function: Hoisting · Attached devices: generator, reducer, driver cab, cable, counterweight · Certificates awarded: CQM, CE, TS, ISO9001:2000 · A-grade 315TM Certificate for producing, installation, rectification, and maintenance of tower crane issued

Wall Mounted Jib Cranes economically provide Hoist coverage for individual use in bays, along walls or columns, or as supplements to an overhead crane or monorail system. Wall Bracket Jib Cranes are the Most Economical Style of Jib Crane Capacities from 1/4 ton to 5 tons, with spans

Jib cranes are a style of cranes in case of which a horizontal portion called the boom or the jib supports a moveable Hoist and is generally attached firmly to a wall or a pillar fixed to the floor. Commonly termed as crane jibs, these machines are either capable of moving in an arc or are fixed in a particular position. The ones that can swing through an angle

Jib cranes are a particular design of design of cranes in case of which a horizontal section called boom or jib, which supports a moveable Hoist, is attached to a pillar screwed on to the ground or is attached to the wall. The crane either remains fixed or can rotate through an arc. A very important piece of equipment in the modern day world, jib cranes satisfy a host of utilities.

the same time protect themselves. Brake motor energized and opened, the braking time is 0.3s, the drive to the start 3Hz frequency drive motor began to turn. Frequency of the drive continuously variable speed up time to the set value, can be seen Hoisting crane speed change is also continuous. With the SA from low gear to high gear switch. K5, K6, K7 state were combined into seven different input frequency, so that the output of seven different frequencies to obtain the lifting speed of seven

In recent years, the use of electric Hoist to install the increasing volume of production, the gourd is also increasing the number of failures, which not only affects the production of the normal operation of a major accident will lead to serious and how to reduce or prevent accidents, improve

eddy current brakes, power brakes, SCR power supply, DC power supply unit and the other the speed governor may cause speeding and 20t lifting mechanism for lifting the molten metal above General bridge crane must have the overspeed protection; 6. Hoisting mechanism should have positive and negative contactor fault protection to prevent the loss of power and brake motors are still in power which led to stall occurred; 7. The protection of all electrical equipment should meet the relevant requirements

of the driver shall not carry out the following acts: (1) the use of parking privileges position limiter; (2) the use of anti-car to hit the brake; (3) examine the process of lifting operations and maintenance; (4) adjustment with load Hoisting, luffing mechanism of the brake, or increase the operating load range; (5) shall not be suspended from the head on top of things through, hanging objects, and may not stand on the lifting arm. Fifth, in strict accordance with the command signal

overhead crane 3, the electric double girder crane 4, the technical parameters Type: Starting weight: () kg; Lifting Height: () m; Span: () m Cart travel distance: () m; specifications: (); Number: () Taiwan Supporting electric Hoist Model: Lifting speed: single speed () m / min; double speed () m / min Car speed: single speed () m / min; double speed () m / min Cart speed: single speed () m / min; double speed () m / min Operation control: () cab operation; () cable ground

/ covers / rotating and reciprocating parts Rotating Upper Structure: turntable electrical collector ring counterweight frame hydraulic pump(s) hydraulic hoses / tubes / fittings hydraulic pressure electrical wiring main Hoist - motor / valves / lines main hoist - wrapping on drum main hoist - minimum (2) rope wraps auxilliary hoist - motor / valves & lines auxilliary hoist - wrapping on drum auxilliary hoist - minimum (2) rope wraps counterweight

A bridge crane (or overhead travelling crane) is defined as a crane comprising a bridge beam or beams mounted to end carriages at each end, capable of travelling along elevated runways and having one or more Hoisting mechanisms arranged across the bridge. A gantry crane comprises a bridge beam or beams, which are supported at one or both ends by legs mounted to end carriages, capable of travelling along runways and has one or more hoisting mechanisms. Bridge

load moment kN.m 1815 Boom length m 13?52 Boom elevating angle ° 0?80° Fixed jib length m 9.15?15.25 Fixed jib offset ° 10,30 Max. single line Hoist speed( at 4th layer with no load) m/min 65 Max. single line elevating speed( at 4th layer with no load) m/min 52 Max. swing speed r/min 1.5 Max. travel speed km/h 1.1 Max.

are engaged in construction work and use cranes or derricks for construction. The standard takes effect Feb. 9, 2011. What equipment is covered? Oregon OSHA’s crane standard covers power-operated equipment used in construction that can Hoist, lower, and horizontally move a suspended load – including, but not limited to: Articulating knuckle-boom cranes Crawler cranes Derricks Mobile cranes Tower cranes The standard also applies to crane attachments such as: Augers

component kits for fabrication of economical cranes. BossBuyer crane components allow economic refurbishment of old cranes. Standardized end carriages, standardized wheel bogies, underslung trolleys, drive units with squirrel cage motors, electric Hoists up to 125 t lifting capacity, conductor systems, contactor control panels, radio remote controls, variable frequency speed control equipments, etc. BossBuyer crane components represent many years of experience in combination with permanent

Jib Crane Definition: A cantilevered boom or horizontal beam arm with bearings, Hoist and trolley. This lifting machine may pick up loads in all or part of a circle around the column to which it is attached. Jib cranes can be sturdy enough to lift a ton or more of weight, or small enough to attach to a truck. While people

mounted on wheels and arranged to travel longitudinally upon one or more rails. 8. Locomotive cranes. - Consisting of a pillar-crane mount,edi on a truck, and provided with a steam-engine capable of propelling and rotat- ing the crane, and of Hoisting and lowering the load. Rectilinear Cranes 9. Bridge cranes. - Having a fixed bridge spanning an opening, and a trolley moving across the bridge. 10. Tram cranes. -Consisting of a truck, or short bridge, traveling viinni1v nn overhead rails.

In some design separate motors may be fitted at each corner of the main bridge. The wheels run on two heavy rails fixed above the floor level along the length of the shop on two girders, called gantry girder. Crab: The Crab consists of the Hoisting machinery mounted on a frame, which is in turn mounted on at least four wheels and fitted with suitable machinery for traversing the crab to and fro across the main girders of the crane bridge. Needless to mention that the crab wheels run

BossBuyer Workstation Jib Cranes work best for light capacities yet offer the same benefits as a Freestanding Jib Crane. These lighter jib cranes come with a Hoist trolley and only require a 6" reinforced concrete floor. Optional portable bases are available to make your workstation cranes portable. For even lighter capacities, try the affordable Tie Rod Workstation Jib Crane with capabilities up

Cranes offer lower headroom than any other brand of articulating jib cranes. Bridge mounted articulating jib cranes offer lower headroom than those of other manufacturers as well and can support nearly any type of manipulator, balancer, or Hoist. BossBuyer Articulating Jib Cranes are designed using a 15% factor for weight of hoist unit and a 50% impact factor. All BossBuyer Articulating Jib Cranes are designed for moderate usage. Consult factory for usage other than moderate and all instances

Your benefits with the new Demag DR rope Hoist optimised for crane applications Increased effidency with extended 2m*service life (1900-hour full load service life) Improved load handling with higher hoist and cross-travel speeds Low-sway load motions thanks to infinitely variable cross

An IIR filtering technique related to input shaping has been proposed for controlling suspended payloads (Feddema, 1993). Input shaping has been shown to be effective for controlling oscillation of gantry cranes when the load does not undergo Hoisting (Noakes and Jansen, 1992; Singer et. al., 1997). Experimental results also indicate that shaped commands can be of benefit when the load is hoisted during the motion (Kress et. al. 1994). On the other hand, feedback control which is well

(1) The rated capacity of a crane shall be legibly marked on each side of the crane. Markings shall be legible from the ground or floor. Each load block of the Hoisting units of the crane shall be legibly marked with its individual rated capacity. (2) Each crane designed and manufactured after January 1, 1971 shall have a service class rating as prescribed in “CMAA #70--Specifications for Top Running

structural damage or risking the safety of the load. 180 degree swivel seat reduces operator fatigue and safety issues by reducing the need for the operator to turn around in his seat while managing a load. Direct Line reeving straight to the Hoisting drums prevents premature wear and tear of wire rope. Superior Paint allows our cranes to maintain their appearance far beyond our closest competitor. Superior painting also buffers the steel from the elements and provides corrosion resistance.

Relative Searches

Hoist Crane, Hoist And Crane, Heavy Duty Crane, Heavy Crane Trucks, Grab Crane, Hoist Crane, Hydraulic Crane, Hydraulic Lift Crane, Hydraulic Truck Crane, jaw crusher for sale,

Email: sales@bossbuyer.com

Skype: bossbuyer

Market Hotline

0086-21-61435-919

Service Hotline:

0086-21-61435-919