Lift Crane Search Result

Railroad crane

Railroad cranes run on train tracks. They move loads in and out of train cars. They can Lift very heavy loads. Railroad cranes can even lift train cars.Train cars are heavy. In an accident, they may leave the tracks. The cranes can pick them up and put them back on the tracks. Railroad cranes can only lift things near the tracks. A railroad

Overhead crane

crane but instead of the whole crane moving, only the hoist / trolley assembly moves in one direction along one or two fixed beams, often mounted along the side walls or on elevated columns in the assembly area of factory. Some of these cranes can Lift very heavy loads.

Floating crane

in bridge building and port construction, but they are also used for occasional loading and unloading of especially heavy or awkward loads on and off ships. Some floating cranes are mounted on a pontoon, others are specialized crane barges with a Lifting capacity exceeding 10,000 short tons (8,929 long tons; 9,072 t) and have been used to transport entire bridge sections. Floating cranes have also been used to salvage sunken ships.

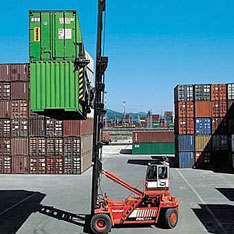

Side lift crane

A side Lifter crane is a road-going truck or semi-trailer, able to hoist and transport ISO standard containers. Container lift is done with parallel crane-like hoists, which can lift a container from the ground or from a railway vehicle.

Stacker crane

A crane with a forkLift type mechanism used in automated (computer controlled) warehouses. The crane moves on a track in an aisle of the warehouse. The fork can be raised or lowered to any of the levels of a storage rack and can be extended into the rack to store and retrieve

Hammerhead crane

The "hammerhead", or giant cantilever, crane is a fixed-jib crane consisting of a steel-braced tower on which revolves a large, horizontal, double cantilever; the forward part of this cantilever or jib carries the Lifting trolley, the jib is extended backwards in order to form a support for the machinery and counter-balancing weight. In addition to the motions of lifting and revolving, there is provided a so-called "racking" motion, by which the lifting trolley,

Self-erecting crane

Self-erecting cranes, generally a type of tower crane, also called self-assembling or "Kangaroo" cranes, Lift themselves off the ground using jacks, allowing the next section of the tower to be inserted at ground level or lifted into place by the partially erected crane itself. They can thus be assembled without outside help, or can grow together with the

Rough terrain crane

Rough terrain Crane is a crane mounted on an undercarriage with four rubber tires that is designed for pick-and-carry operations and for off-road and "rough terrain" applications. Outriggers are used to level and stabilize the crane for hoisting. These telescopic

Jib crane

A jib Crane is a type of crane where a horizontal member (jib or boom), supporting a moveable hoist, is fixed to a wall or to a floor-mounted pillar, which is a style of cranes in case of which a horizontal portion called the boom or the jib supports a moveable

Bulk-handling crane

Bulk-handling Cranes are designed from the outset to carry a shell grab or bucket, rather than using a hook and a sling. They are used for bulk cargoes, such as coal, minerals, scrap metal etc.

Crawler Crane

A crawler crane is a crane mounted on an undercarriage with a set of tracks (also called crawlers) that provide stability and mobility. Crawler cranes range in Lifting capacity from about 40 to 3,500 short tons (35.7 to 3,125.0 long tons; 36.3 to 3,175.1 t). Crawler cranes have better manoeuvrability and can be quickly relocated at different locations on a project site. However, for shifting to another project

Telescopic crane

of tubes fitted one inside the other. A hydraulic or other powered mechanism extends or retracts the tubes to increase or decrease the total length of the boom. These types of booms are often used for short term construction projects, rescue jobs, Lifting boats in and out of the water, etc. The relative compactness of telescopic booms make them adaptable for many mobile applications.

Tower crane

Tower crane is a modern form of balance crane that consist of the same basic parts. Fixed to the ground on a concrete slab, tower cranes often give the best combination of height and Lifting capacity and are used in the construction of tall buildings. The base is then attached to the mast which gives the crane its height. Further the mast is attached to the slewing unit that allows the crane to rotate. On top of the slewing unit there

Giant Cantilever Crane

Also known as a hammerhead crane, the giant cantilever crane is a fixed jib crane consisting of a steel braced tower, on which revolves a large horizontal double cantilever. The forward part of this cantilever or jib carries the Lifting crab, and the jib is extended backwards in order to form a support for the machinery and counterbalance.

port crane

for heavy work at seaports, river ports and freight yards and it can be equipped with hoisting hooks and grab buckets. Port Crane is applicable to various types of cargos and can be used for handling containers. The Port Crane is mainly composed by Lifting mechanism, rotating mechanism and slewing mechanism. These three mechanisms can work separately or jointly. The single-jib or four-jib Port Crane can be chosen according to different requested lifting capacities.

Cranes

on heavy machineries. Of all the heavy machines cranes acquire an important position as they are involved in the building and maintenance of huge projects. Crane machines are the huge tower like machineries having ropes meant to Lift or to lower any heavy devices. Hence they are also referred as lifting cranes. Cranes are not permanent structure. In fact it is a temporary structure either fixed in the ground or mounted on certain vehicles. Cranes are operated either through

Tower Crane

in the building. As each floor is built, the crane is moved up. Tower cranes are one of the most important device that is used for the construction of huge buildings. They are a common fixture at any major construction site. They are used to Lift steel, concrete, large tools like acetylene torches and generators, and a wide variety of other building materials. Tower cranes have distinct advantages over conventional lattice boom crawlers or truck cranes because the boom or jib looms high

Bridge Crane

Bridge Crane is a heavy machinery that is designed to build or fix a bridge. It operates on two tracks and has four way horizontal movement. Bridge cranes cover rectangular area and can be floor supported or hung from the ceiling. The main components of

Floating Crane

A floating Crane refers to a type of sea vessel which has a crane mounted on it. In earlier days, floating crane designs were nothing more than old ships transformed to include a huge crane mounted over the deck. Eventually, cataraman, semi-submersible designs

Gantry Crane

Gantry Cranes are those cranes which are generally used for moving heavy loads. They are a common type of portable material handling equipment used in job station or secondary task areas. Gantry cranes are quite similar to overhead cranes except that

Mobile Cranes

Cranes are the huge tower like machineries having ropes meant to Lift or to lower any heavy device. Cranes are not permanent structure. In fact it is a temporary structure either fixed in the ground or mounted on certain vehicles. Cranes are operated either through cab operator or through infrared or radio signals.

FAQ About Lift Crane

- Types of Cranes

- Ceiling Mount Articulating Ceiling Type Jib Crane

- Construction and Maintenance of Cranes and Lifting Appliances

- Testing and Examination of Cranes and Certain Lifting Appliances

- Stability of Cranes and Lifting Appliances

- Tower crane lifting boom

- Tower Crane Safety Devices

- YGMT Crane types

- Safe Crane Operations

- Cranes, lifting appliances and fork lift trucks

- Coupled Cranes

- Safe Access To, and Egress From, Cranes or Lifting Appliances

- Brakes, Controls, Derricking Jibs and Cabins for Operators of Cranes

- Crane Lifting Operations - Operators of Cranes and Certain Lifting Appliances

- Crane Lifting Operations - Signalling

- Safe Means of Access and Egress and Safe Place of Work for Persons Engaged in Lifting Operations

- Crane Lifting Operations - Load Not To Exceed Safe Working Load

- Crane Lifting Operations - Secureness of Loads

- Crane History

- Raw Materials of manufacture cranes

- Cranes,overhead traveling crane,Construction cranes,Tower cranes,Mobile cranes,Articulating cranes

- The Manufacturing Process Of Crane

- Crane Safety and Quality Control

- Jib crane motions

- Gantry crane introduce

- lifting crab of a EOT crane

- News conference addresses concerns over tower crane safety

- WALKING CRANE FOR OPERATION BY POWER OR HAND

- Column Crane

- Design and Optimisation of Crane Jibs for Forklift Trucks

- Overhead Crane and Bridge Crane

- Cranes and hoists operating rules

- Double Legged Gantry Cranes

- FACTORS BEHIND THE SELECTION OF CONSTRUCTION EQUIPMENTS

- PORTABLE TRUCK-MOUNTED CRANE BOOMS

- Guy Derrick

- Jacking Towers

- Hydraulic Telescoping Gantries

- Truck Carriers

- All-Terrain Carriers

- Tower-mounted crane

- Crane and Mobile Crane

- Mobile Crane Clearances

- Crane Classification

- Crane Overloads and Crane Test Loads

- MOBILE CRANES INTRODUCTION

- A New Approach for Controlling Overhead Traveling Crane Using Rough Controller

- Crane Rigging a Load and Crane Overloading

- Material Handling Solutions

- Radio Communication Can Assist Container Gantry Crane Operators in Marine Terminals

- Luffing Tower Crane

- Mini crawler cranes

- Self-Raising Tower Crane

- Popular Construction Equipments or Construction Machineries

- Crane Gantry

- Industrial Cranes

- Stainless Steel Jib Cranes

- Jib Cranes

- Articulating Jib Crane

- Portable Jib Crane

- Self Propelled Cranes

- Lorry Mounted Cranes

- Crane Steel Structures Test Problems

- Crane Control program analysis and comparison

- Electric Hoist Failure Analysis and Treatment

- Metallurgical cranes on the technical requirements for special work

- General requirements of the safe operation of crane drivers

- Customer Order cranes should know a few basic parameters

- Crane Preventive Maintenance Checklist

- Question About Tower Crane - 1

- Crawler Crane QUY50

- Mast Style Jib Crane

- Oregon OSHA’s new crane standard for the construction industry

- Crane Component

- BossBuyer Jib Cranes

- Wall Mounted Jib Cranes

- Electric Overhead Travelling Crane (EOT Crane) Parts

- Workstation Jib Cranes

- BossBuyer Gantry Cranes

- Articulating Jib Cranes

- Wall Traveling Jib Cranes

- Bottom-Slewing Tower Cranes Structure and Configuration

- Gin Pole Derrick

- Classification of Crane Anti-sway devices

- Principle of the Crane Anti-Sway device

- YJCrane Gantry Crane

Cranes - these are Lifting devices designed to raise materials by means of rope operation and move the load horizontally within the limitations of any particular machine. The range of cranes available is very wide and therefore choice must be based on the loads to be

Bridge Crane to allow the jib to swing under an obstruction or outside the normal coverage of a bridge cranePlatform mounting can deliver the benefits or an articulating jib to multiple work cellsEffortless rotationCan be used with hook mounted Lifting devices (electric, air, or vacuum)

Construction and Maintenance of Cranes and Lifting Appliances Cranes and lifting appliances must be of good construction and be properly assembled. This means that they must be of good design which includes, amongst other things, being well built for the purpose for which

the type of person who would carry out the duties of testing and examining for the purpose of these Regulations. 6. The person should:- a) have the requisite knowledge and experiences, both theoretical and practical, of the type of crane or Lifting appliance to be tested and examined; to certify with confidence that it is capable of being used safely and it is free from patent defect and suitable in every way for the duty in which the crane or lifting appliance is to be used. Additionally,

Where a crane or a Lifting appliance is to be used on a slope or on uneven or soft ground, precautions must be taken to prevent overturning. This can be done, for example, by reducing the slope, levelling the ground or by using suitable supports. If a situation

Tower crane Lifting boom comprises main boom and fixed jib, the structural type is lattice structure of four tubular chords with intermediate equal section and two end variable section, main boom chord and web rod are made of domestic high quality tube, with

hoist limit switch, anemometer, level gauge, hydraulic overflow valve, counterbalance valve, two-way hydraulic lock, stewing warning lamp and travel warning lamp, etc. Load Moment Limiter Detection function: automatically detect boom angle and Lifting load. Display function: real time display current actual load, working radius and boom angle. Warning function: automatically send out warning and stop crane operation when detecting actual load exceed rated load, boom out of limit angle. Detection

YGMT. Its marketing shares, including metallurgical crane, charging crane, slab tong crane, magnet crane; hydropower station bridge/gantry crane, common bridge/gantry crane, forging crane, quenching crane, load and unload crane, dry coke quenching Lifter, Nuclear power station polar crane, bridge girder erection machine and other special cranes. YGMT has provided 6000 cranes in the industry field of metallurgy, hydropower station, nuclear power station, heavy mining, machinery, energy, railway,

a load Never hoist two or more separately the capacity of the crane even if the combined weight is with in the capacity of the craneNever wrap the hoist line around the load Never electrical load and/or hoist-limit switches or warning devices Start Lifts slowly and avoid shock loading Always place the hook directly over the center of gravity or the designated lifting point Use taglines to help maneuver the load Never use taglines to swing the loadBefore hoisting the load, check for loose parts that

The Regulations apply to cranes and Lifting appliances used in the manner described in Regulation 2. The terms "cranes" and "lifting appliances" are defined legally in Regulation 1 which deals with the interpretation of various expressions used in the Regulations. "Crane" means:-

The use of more than one crane to Lift the same load is sometimes called a "tandem lift". This is sometimes necessary when the load to be lifted exceeds the safe working load of a single crane, and a crane of an appropriate capacity for the load is not available. Lifting a load with two

Safe means of access and egress must be provided for operators of cranes and Lifting appliances. The equivalent standard of safety must also be provided for persons carrying out work on the crane or lifting appliance particularly work involving the examination, lubrication or repair where the person carrying out the work

Brakes, Controls and Other Safety Devices Every crane or Lifting appliance must be provided with an efficient braking system. The system must be capable of sustaining any load to be raised, lowered or suspended within its capacity. This requirement does not apply to self-sustaining cranes or hand operated

A certificate of competence must exist for every operator of a crane, excavator, fork Lift truck, mechanical grab, mechanical shovel and piling machine. The certificate must be issued by The employer of the operator; or The owner of the equipment which the operator is using An operator who has not been certificated

Where the load is not clearly visible or the hook of the crane or Lifting appliance is not clearly visible to the operator, a signaller (banksman) must be used to transmit the slingers instructions to the operator. All signals must be clear and concise and should, if they are visual signals, conform to the

This requirement, involving the provision of safe means of access and egress, is directed towards the employees who are involved in Lifting operations. This means the work involved in lifting operations, which includes the attaching of loads, using lifting gear, to cranes and lifting appliances prior to the loads being raised, lowered or suspended. Where dock workers need

The safe working load of a crane or a Lifting appliance must never be exceeded under normal operating conditions.There are only two exceptions to this requirementWhere a proof load test is being carried out on a crane or lifting appliance under the supervision of a competent person for the

Loads must be secured whilst being raised, lowered or suspended - they must not be capable of being easily displaced. Loads must be properly secured to the hook or other device of the crane or Lifting appliance and where the load comprises a number of parts, the load must be so constructed that each part is stable and not likely to become loose.Preventative measures must be taken to ensure that extraneous objects do not become displaced during

A crane is a machine that is capable of raising and lowering heavy objects and moving them horizontally. Cranes are distinguished from hoists, which can Lift objects but that cannot move them sideways. Cranes are also distinguished from conveyors, that lift and move bulk materials, such as grain and coal, in a continuous process. The word crane is taken from the fact that these machines have a shape

The most important factor in determining the properties of carbon steel is the amount of carbon present, which ranges from less than 0.015% to more than 0.5%. For structures that require great strength, particularly in cranes designed to Lift very heavy objects, a variety of substances known as high-strength low-alloy (HSLA) steels are used. HSLA steels contain relatively low levels of carbon, typically about 0.05%. They also contain a small amount of one or more other elements

Very few machines exist in as wide a variety of designs as cranes. Before the crane is constructed, the manufacturer must consider the site where it will be used and the weight it will need to Lift. In addition, cranes are often modified to suit the needs of the user. For these reasons, it is not much of an exaggeration to say that no two cranes are exactly alike. Cranes used for industrial purposes are generally designed to remain permanently

tubes, such as those used to form the latticed booms of large cranes, may be made by bending sheets of steel and welding the long sides together. They may also be made by piercing steel rods with a rotating steel cone. The cables used to Lift weights are made from steel wires. To make wire, steel is first rolled into a long rod. The rod is then drawn through a series of dies which reduce its diameter to the desired size. Several wires are then twisted together to form cable.Steel

would weaken the crane. Welds and bolts joints are inspected as well. The United States government sets specific regulations through the Occupational Safety and Health Administration that limit the weight that a specific crane is allowed to Lift. The Crane Manufacturers Association of America sets its own safety standards which exceed those required by the government. Special devices within the crane prevent the user from attempting to lift a weight heavier than that allowed. A completed

Jib crane have the following motions: Hoisting motion Derricking or luffing motion Slewing motion Long travel motion Hoisting motion: It is used to Lift or lower the load. This is usually achieved by steel wire ropes being affixed to a crane hook or a grab hanging from the outer end of the jib. The rope is applied through some receiving arrangement and controlled and operated by a winch system.Derricking

the two legs supporting the shape of a gantry-type crane bridge. This crane orbit on the ground, mainly used in open yard storage, shipyards, power plants, ports and railway stations to carry out cargo handling and installation. Gantry cranes Lifting bodies, car bodies and bridge operation structure, with essentially the same bridge crane. As a result of large-span cranes are mostly used to run the respective drive means to prevent operation of a crane skew have increased resistance, or even

The Lifting crab of a EOT crane is an independent two motion machine and consists of the hoist machinery built on to a frame, which is mounted on runner wheels, and driven by a motor through suitable gearing. The crab is also known as trolley. Various

and have been used since the 1940s in construction projects. “Of the more than 3,000 tower cranes in North America, about 2,100 are in use on any given day,†said Dandrea. “With a conservative estimate of 50 Lifts daily per crane, more than 105,000 lifts are executed safely every day.†Standards needed Bill Smith, president of NationsBuilders Insurance Services Claims and Risk Management Services (NBIS), once was a crane operator

erection and for setting them in position. For work of this description these cranes are exceedingly convenient and economical.Estimates will be furnished on receipt of information as to whether to be operated by hand or power, maximum load to be Lifted, effective radius desired, length of longitudinal travel and height from floor to ceiling.

and around which it is therefore desirable that the cranes should rotate. Thus arranged they have all the convenience and applicability of ordinary jib cranes.Estimates will be furnished on receipt of information as to the maximum load to be Lifted, height from floor to ceiling, effective radius desired, and distance from center to center of column, where they are so near as to limit the sweep of the crane. By limiting the latter to less than an entire revolution, the jib may be lengthened

in order to check the numerical results and the methodology of design. The principal conclusions that are obtained are that it has been developed a methodology for the design, calculation and optimization of crane jibs for fork-Lift trucks, adapting the regulation UNE-58536 for movile cranes, becouse the norm UNE-1726 is not too much restrictive; so it was necessary to define the load cases, the boundary conditions, the loads, the materials, the welds models,

for at least ten tons, double girder bridge cranes are normallyutilized. With the girder box configuration, one major benefit is the lower deadweight with a stronger integrity of the overall system. Onemore advantage will be the hoist so as to Lift the objects and the bridge that spans the area covered by the crane, together with atrolley so as to move along the bridge. Overhead Crane Application Overhead cranes are most generally used within the steel business. The steel is dealt with

operators shall comply with the following rules while operating the cranes and hoists: Do not engage in any practice that will divert your attention while operating the crane. Respond to signals only from the person who is directing the Lift, or any appointed signal person. Obey a stop signal at all times, no matter who gives it. Do not move a load over people. People shall not be placed in jeopardy by being under a suspended load. Also, do not work under a suspended

Gantry, Double Legged Single Girder 5 1 Wallace, 12' 0", Tri-Adjustable Semi-Gantry Cranes for Sale Semi-Gantry (P&H) Single Girder, TR 5 2 30'-0" Span, 20'-0" Lift, 460V, P&H Hoists Semi-Gantry (P&H) Single Girder, TR 10 2 30'-0" Span, 20'-0" Lift, 460V, P&H Hoists Crane Bridges Only for Sale Bridge Only-No Hoist Double Girder, TR

selection. A number of computer programs have been developed to assist in the equipment-selection process. Similarly, commercial software is available that offers solutions for the selection and location of a specific crane model and for Lift planning (Meehan 2005). Examples are Compu-Cranc and LPS (NCI 2006). Cranimation and Tower-Management (Cranimax 2006), LiftPlanner (LiftPlanner Software 2006) and MethoCAD (Progistik 2006). These software packages, commonly used by engineering

Another type of Lifting equipment is the portable boom attached to a flat-bed truck to load and unload material. This type of boom has comparatively little horizontal reach flexibility but does swing on a turntable support mechanism at its base on the truck. These booms

be used to provide leverage for pulling the derrick around manually. Another method, sometimes used on steel erection derricks, makes use of a handwheel and gearing so that one person at the base of the derrick can swing the boom. The topping Lift is attached to the mast just below the gudgeon pin. The topping and load lead lines come into the mast at the top and above the boom foot, respectively, and run down the center of the mast. The lead lines run into the derrick base, which is

can be inserted and support the load. With the crossbeam safely seated, the jacks can be retracted in preparation for the next increment of climbing. Thejacks are short and remain in place; climbing is accomplished by inserting solid-steel Lifting pistons each time thejacks are retracted. Between strokes, previously placed lifting pistons rest on the dog. There are twojacks located at the base of each tower; the lifting pistons are inserted, and the lock plates are located at the

Telescophig gantries are typically used for heavy Lifting where mobile cranes or derricks are not feasible, where classic "jack and slide" procedures are awkward, or where other conditions make use of the gantry the most economical means to perform the work required. These systems first came into

truck chassis. The mounting must meet specifications for frame stiffness, weight, and axle limitations. A boom truck, rated for up to 50 tons and reaching as high as 180 feet (55 m), has an advantage of being able to transport the loads it Lifts. Carriers must be designed for movement about the jobsite and on the highway. To accommodate those extremes, transmissions with as many as 33 forward gears are provided, and some carriers are equipped with special creeping gears as well.

surfaces while the crane is in motion or is static. New models are continuing to appear, and models with more than 800-ton (700-t) capacity are available. Though pick- and-carry operations are usually permitted, outriggers are used for most Lifting.

to be determined by its suitability to the work than by the country where the work is taking place. At least that is the broad picture; contractors in some localities cling longer to traditional practices than others. Tower cranes are the Lifting machines of choice worldwide for most mid- and high-rise building construction. They are used also on expansive sites where the broad hook sweep and the relative ease of coordinating multiple tower cranes is an advantage. There are niche

of aviation belongs to the barnstormers and bush pilots who pushed their rudimentary craft to the limits with hardly a thought for risk. Likewise, crane operation was once a seat-of-the-pants skill governed largely by the notion that Lifting equipment could be used right up to the point of tipping over. Both cranes and aircraft of early vintage were machines with modest capabilities that responded almost like extensions of the operators themselves. Machines were relatively small

will swing into nearby structures. The tail end of the superstructure requires a clear swing path, too. And, after completing the work, the crane must be able to extricate itself and lower its boom for dismantling. Far from all mobile-crane Lifts run against these constraints, but they are common enough to demand attention. It is embarrassing, to say the least, to send a crane to a job only to find that it is incapable of placing the loads where needed. Embarrassment may be only

the different crane classifications, as generally described by CMAA, are as follows: Class A (Standby or Infrequent Service): This service class covers cranes where precise handling of equipment at slow speeds with long idle periods between Lifts are required. Capacity loads may be handled for initial installation of equipment and for infrequent maintenance. Typical examples are cranes used in powerhouses, public utilities, turbine rooms, motor rooms, and transformer stations. This is the

Crane Overloads - What is allowed? On a routine basis, the amount of load a crane can "legally" Lift, as a percent of its rated capacity, is 100.0000%, with a tolerance of +.000%/-100% (get the idea?). All kidding aside however, ASME B30.2 does provide for what is termed "planned engineered lifts" where it is necessary to make very occasional lifts

cranes is the different ways in which a standard model can be put to use by the mere change of attachments, such as electromagnets or buckets for handling of bulk materials. Performances factors in which various cranes differ include Lifting capacity, radius of operation, hoisting speed, speed of travel and speed of rotation of the boom. Lifting capacity of models usually purchased for industrial use ranges from 5 to 30 tonnes. The radius of operation depends, of course,

of the proposed rough controller is satisfactory. The crane can be considered as one of the most important tools used in industry to transfer loads from one desired position to another. Usually cranes have very strong structures in order to Lift heavy payloads in factories, in building construction, on ships, and in harbors. Until recently, cranes were manually operated. But when cranes became larger and they are being moved at high speeds, their manual operation became difficult. Consequently,

with the base only on the live end and the U-bolt only on the dead end. Follow the manufacturer's recommendations for the spacing for each specific wire size. Determine the center of gravity and balance the load before moving it. Initially Lift the load only a few inches to test the rigging and balance. Crane Overloading Cranes or hoists shall not be loaded beyond their rated capacity for normal operations. Any crane or hoist suspected of having been overloaded shall be removed from

Material Handling Solutions For Your Unique Applications Since 1977, YJM has been an innovator and leader of Lifting loads in a work cell. YJM began as a manufacturer of Gantry Cranes and manually or power operated jib Cranes, including wall bracket, wall cantilever, free standing, and mast type models. In 1986, YJM added a line of Work Station Cranes,

gantry crane operators load and discharge hundreds of containers in a systematic fashion. The crane operators rely on their line of vision and on signals or directions from employees on the ship and on the ground below to guide them in their Lifts. Risk of injuries can be reduced by the use of radio communication by the crane operators and longshore personnel. Hazards of Container Operations Container ships come in and out of ports on a regular basis. At each port, containers must

Tower Crane with Maximum Load of 16t and Working Radius Ranging from 15 to 60m Luffing Tower Crane Key Specifications/Special Features: Maximum Load: 16 T Maximum working range: 60 m Tip load: 2.9 T Working range: 15 to 60m Lifting capacity: 16-3.7 T Freestanding height: 42.1m Anchored high: 200m Derricking speed: 1 min 40S Slewing speed: 0-0.7r/min

other cranes simply would not be suitable for. The cranes low headroom allows them to be used indoors or even underground. The powerful rubber tracked CX-8T with 360 degrees slew and 4 stage telescopic boom, Lifts 8 tonnes, yet occupies a footprint of only 3.48 x 3.48 metres. The compact size allows easy transport by air, water, rail and road. Advantages of mini crawler cranes Compact and Tough Suits all types

for the construction of tall buildings and equipment installation, is a type of self-raising multi-purpose tower crane equipped with level arm support, and it allows trolley derricking and upper slewing. its jib maximum length is 70m, with maximum Lifting load of 12000KG. Main features of the tower crane are given below: · TOWER CRANE WITH CE (FOR EUROPEAN MARKET), ISO9000 CERTIFICATE(IN CHINA.) · TOP 1 IN GUANGDONG PROVICE, CHINA · Have 24 Years Experience In This Area · 800

used to compact dirt, asphalt, gravel, and concrete in roads and construction sites. Rotary Tiller: This equipment is a motorized cultivator with a rotating blade. It is mainly used to work in the soil. Crane: A crane is used for lowering and Lifting materials. They are mostly temporary tower structures equipped with pulleys and cables and used in construction sites. Drag line excavation systems: A popular heavy construction machine used in surface mining and civil engineering. The

A crane, which is equipped with a derrick or tower, is used to lower and Lift materials with the use of pulleys and cable. Heavy equipment manufacturers and the construction industry use cranes in various activities connected with their process. Cranes used in the construction industry are mostly temporary structures either

yachts and cargo ships. There are many variations of this type. The deck cranes used in ports are typically bigger and have a longer arm span. The ranges of deck cranes may include cylinder and wire luffing cranes, gantries, grab cranes and heavy Lift Cranes. Big cargo ships would require heavy lifter cranes. Sometimes, cranes installed are dependent on the products a cargo ship carries. Yachts however would only need a smaller deck crane with shorter reach that can be sustained by the vehicle

of Stainless Steel Jib Cranes Reduce contamination in processing environments Safely handle oversized loads in sanitary environments Reduce crane corrosion over surface finishing and metal treatment tanks Clean overhead Lifting equipment with the same compounds used on other wash-down processing equipment Service mixers, pumps and motors on-site with integrated jib cranes without other non-sanitary equipment

mechanism whereby they can be rotated using a wheel and made to turn in an angle up to 360 degrees. All crane jibs do not possess arms that are capable of swinging – some are manufactured with fixed arms. In such cases, the lowering and Lifting of the loads are most often done with the help of a hoist which is either electrically or manually controlled. Jib cranes that are fixed to walls or floors generally have limitations on their range of operation and this makes the process

[caption id="attachment_251" align="alignleft" width="250" caption="Articulating Jib Crane"][/caption] Unlike other jib cranes, articulating jib cranes have a hinge or joint at the center of the horizontal section that Lifts the load. This feature enables the user to bend or fold the arm if required. Since it can be folded, articulating jib cranes are easy to maneuver in small areas with space restrictions. Mostly used in warehouses, large departmental stores

etc. The military forces also use these machines to serve a variety of purposes. Some of them are called portable jib cranes simply because of the fact that they can be moved from one place to another with the assistance of a fork Lift. Although the amount of weight that they can carry is significantly less than that of a fixed or wall mounted one, portable jib cranes today are an important piece of machinery. By attaching a simple fork lift, any standard design of these

one operator position from which the crane is controlled and the vehicle driven. The road speed of this type of crane is generally low usually not exceeding 30km p/h. A variety of self propelled crane formats are available ranging from short height Lifting strut booms of fixed length to variable length lattice booms with a fly jib attachment. Typical specification main boom length 38,000 lifting capacities for a 24, 000 main boom length 1. stabilised on outriggers 31-4 tonnes at 4,000

cranes consist of a lattice or telescopic boom mounted on a specially adapted truck or lorry. They have two operating positions: the lorry being driven from a conventional front cob and the crane being controlled from a different location. The Lifting capacity of these cranes can be increased by using outrigger stabilising jacks and the approach distance to the face of building decreased by using a fly jib. Lorry mounted telescopic cranes require a firm surface from which to operate and because

amount set under the main beam in the reading, both the actual elastic deformation of the main beam, as well as bearing rail beams, wagon wheel assembly space, car assembly asked the gap, cart tracks and car track deformation, deformation of the Lifting rope and so on. Plant installed in the concrete structure for the crane, the elastic deformation of the main beam than the previous several other large and more space and orbital assembly deformation is negligible; but for steel plant in the crane,

value, can be seen hoisting crane speed change is also continuous. With the SA from low gear to high gear switch. K5, K6, K7 state were combined into seven different input frequency, so that the output of seven different frequencies to obtain the Lifting speed of seven different stops, SA through the block back to zero, the inverter output frequency in the deceleration time continuous decrease. When the output frequency is equal to the frequency of cervical braking closed (6Hz) time. Mechanical

of electrical or line repair or replacement, as confirmed Lord, trouble-free control loop, before re-testing; (3) the hoist motor terminal voltage is lower than 10% of rated voltage, the motor starting torque is too small, so do not moving cargo Lifting hoist, and can not work, check with a multimeter or voltage meter and other measuring motor input voltage is indeed due to low voltage, the motor can not be started, the need to return to normal after system voltage such as using electric hoist.

AQSIQ "quality to do special ?2007? 375" document, published in the use of non-metallurgical crane for Lifting the molten metal in the remediation requirements, as follows, for everybody to learn, discuss and exchange. (A) has been used for general overhead crane lifting molten metal, shall be replaced in order to comply B/T7688.15-1999 "Metallurgical

should be given intermittent tone. Fourth, during normal operation of the driver shall not carry out the following acts: (1) the use of parking privileges position limiter; (2) the use of anti-car to hit the brake; (3) examine the process of Lifting operations and maintenance; (4) adjustment with load hoisting, luffing mechanism of the brake, or increase the operating load range; (5) shall not be suspended from the head on top of things through, hanging objects, and may not stand on the

1, electric single-girder crane 2, electric single-girder overhead crane 3, the electric double girder crane 4, the technical parameters Type: Starting weight: () kg; Lifting Height: () m; Span: () m Cart travel distance: () m; specifications: (); Number: () Taiwan Supporting electric hoist Model: Lifting speed: single speed () m / min; double speed () m / min Car speed: single speed () m / min; double speed ()

- motor / valves & lines auxilliary hoist - wrapping on drum auxilliary hoist - minimum (2) rope wraps counterweight / mounting swing gear box electrocution warning sign (outside) counterweight warning sign Main Boom: Lift cylinder(s) telescoping cylinder(s) hydraulic hoses / tubing & fittings holding device boom sections alignment wear pads equal extension sheaves hoist line dead end wire rope retainer boom hinge pin boom head

locking nuts and pins? A. Daily B. Weekly C. Monthly When climbing a ladder what safety position should you hold? A. Centre rung of ladder B. Outside rail of ladder C. Does not matter where you hold on to If your crane is fitted with a Lift, how often should it be checked and tested by a competent person? A. Six months B. Weekly C. Yearly Tower cranes must be load tested in accordance with BS7121. How often should this be done? A. 6 years B. 4 yearly, after each erection of

[caption id="attachment_403" align="aligncenter" width="413" caption="crawler crane quy50"][/caption] Item Unit Parameter Max. Lifting capacity Boom t 50 Jib t 4 Max. load moment kN.m 1815 Boom length m 13?52 Boom elevating angle ° 0?80° Fixed jib length m 9.15?15.25 Fixed

available in two series: 200 Series Mast Style Jib Cranes - Full Cantilever Lower cost alternative to foundation mounted free standing jibs No mounting foundation required Allows maximum use of headroom to provide the highest possible Lifting distance Standard capacities to 5 tons Standard height and spans to 20 feet Greater capacities, heights, and boom spans available upon request Motorized rotation available 201 Series Mast Style Jib Cranes - Drop Cantilever Identical

to crane attachments such as: Augers and drills Clamshell buckets Concrete buckets Hooks Personnel platforms What equipment isn’t covered? Equipment not covered includes: Machinery converted or adapted for non-hoisting/ Lifting use Power shovels, excavators, wheel loaders, backhoes, loader backhoes, and track loaders – even when used with chains, slings, or other rigging to lift suspended loads Digger derricks used for augering holes for poles carrying

fabrication of economical cranes. BossBuyer crane components allow economic refurbishment of old cranes. Standardized end carriages, standardized wheel bogies, underslung trolleys, drive units with squirrel cage motors, electric hoists up to 125 t Lifting capacity, conductor systems, contactor control panels, radio remote controls, variable frequency speed control equipments, etc. BossBuyer crane components represent many years of experience in combination with permanent development in design.

Jib Crane Definition: A cantilevered boom or horizontal beam arm with bearings, hoist and trolley. This Lifting machine may pick up loads in all or part of a circle around the column to which it is attached. Jib cranes can be sturdy enough to lift a ton or more of weight, or small enough to attach to a truck. While people will often rig homemade

strength is not a limiting factor. Wall bracket kits include all components except the I-beam, tie rod and mounting hardware, which if preferred, can be purchased locally. IMPORTANT NOTE: This equipment is not, in any way, designed for Lifting, supporting, or transporting humans. Failure to follow the specified load and mounting limitations can result in serious bodily injury and/or property damage. Jib cranes should not be supported from any existing building structure without

2 No’s Wheel of the bridge– At least 4 No’s Crab (without auxiliary hoist)– 1 No’s Hoisting machinery set– 1 No’s Wheels of crab– At least 4 No’s Bottom Block (without auxiliary hoist)– 1 No’s Lifting hook– 1 No’s Rail on the gantry girder for crane movement– 2 No’s Rail on the bridge for crab movement– 2 No’s Operators cabin– 1 No’s

duty applications. Capacities vary up to 11,000 lbs. and spans reach 16 feet. Circular coverage workstation jib cranes offer 200º or 360º of rotation. Workstation jibs offer easy, ergonomic movement for applications requiring repetitive Lifting and transferring of loads. An operator could be pushing a 1000 lb. load; however, the operator will experience the force of approximately 10 lbs. to begin moving the load and 8 lbs. to continue moving the load (100 to 1 ratio). Also,

Dependable and versatile, BossBuyer Gantry Cranes offer cost effective Lifting portability that can withstand the heaviest of loads. Easily assembled and disassembled, a BossBuyer Gantry Crane can be used indoors or outdoors, whether mounted or mobile. Gantries are successfully utilized across

factor. All BossBuyer Articulating Jib Cranes are designed for moderate usage. Consult factory for usage other than moderate and all instances of high cycle rates or high impact applications such as high-speed air or electric hoists, vacuum Lifters, or magnets.

Primarily used for long lateral movement under an overhead crane, the BossBuyer Wall Traveling Jib Cranes provide Lift under a large overhead crane without interfering with the overhead crane. This enables workers to continue lifting material without waiting for a larger overhead crane to become available. BossBuyer Wall Traveling Jib Crane end trucks use channel

crane configurations altogether, the jib of the common bottom-stewing crane can usually be raised, though not in a sharp angle (commonly up to 300), while maintaining trolley movement. This grants the initially height- limited crane an additional Lifting height. Some models have an articulated jib, in which the part closer to the mast is horizontal and the outer part can be angled upward.

Agirrlwle is the most elemental form of derrick-it could be described as primitive--essentially a leaning mast incapable of swinging and held in place by guys. With no boom, Lifting is done from a load fall at the tip of the mast. Large and small gin poles find roles quite distinct from one another. In the middle range alternative lifting devices are more practical, and so middle-sized poles are a rarity. Long heavy-duty

measuring the actual swaying, by means of an estimator embedded in a drive controller or any external logic controller. The principle is that the anti-sway controller calculates an acceleration (a progressive speed profile) that enables the Lifting equipment to reach a given movement speed without the load swaying. Since there is no way to determine the actual state of the physical system, proper operation requires a zero initial swaying and insignificant external disruptions, such as

actions of an experienced operator, returning to a stable state of equilibrium may take several seconds. The swaying of the load only appears during the linear motion of the gantry crane (x movement) or when the trolley moves (y movement). Lifting the load following the z axis does not generate any swaying. The Anti-Sway principle is based on using a load position estimator and determines the difference between the perpendicular and the trolley. It will be noted that in this equation

The gantry cranes that Lift your productivity. YJCrane is a company that has always cared about engineering and manufacturing practical, robust, and durable lifting solutions. For more than 20 years, we have been innovating our equipment with thoughtful, customer requested

Relative Searches

Lift Crane, Jib Crane, Jib Boom Crane, jaw crusher for sale, Hydraulic Truck Crane, Lift Crane, Light Crane, Loading Crane,

Email: sales@bossbuyer.com

Skype: bossbuyer

Market Hotline

0086-21-61435-919

Service Hotline:

0086-21-61435-919